Tesla and its Gigafactory run with Lily Bearing

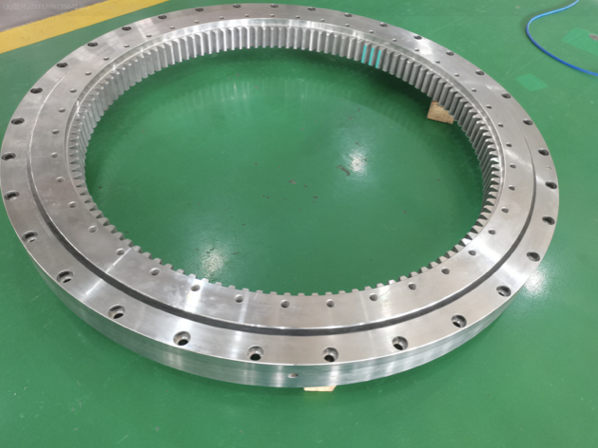

LILY has supplied assistance in Tesla’s create new products at the Gigafactory, a special custom slewing bearing made by Lily Bearing will soon start...

High-temperature bearings are specifically engineered to endure extreme heat, typically ranging from 180°C to 330°C.

In contrast, standard bearings are designed to handle temperatures up to +120°C for open types and +80°C for sealed types.

In this blog, we will provide an in-depth comparison between high temperature bearings and standard bearings.

A standard bearing is a type of bearing designed to support rotational or linear movement in machinery and equipment under normal operating conditions.

Household Appliances:

Automotive Components:

General Industrial Machinery:

Carbon steel is a common material for bearings because of its strength and wear resistance.

It works well for general-purpose applications where high corrosion resistance isn't needed.

This makes it suitable for lower load, lower speed, or less demanding environments.

Chromium steel, specifically GCr15, is a high-quality material commonly used in high-performance bearings.

It contains around 1% chromium, which provides enhanced hardness.

GCr15 steel is widely used in applications requiring high load capacity and high speed.

It is commonly found in automotive and industrial machinery bearings for its long service life.

Bearings made from materials like carbon steel or chromium steel (GCr15) typically have a temperature range of -20°C to +120°C.

This range is suitable for most general-purpose applications. The operating temperature remains effective when it stays within these limits.

In this temperature range, the bearings maintain their strength, stability, and performance.

High temperatures can weaken the bearing material, causing it to deform and wear faster.

Cold temperatures can make the material brittle and prone to cracking.

At high temperatures, lubricants can break down, causing more friction and damage.

In cold conditions, the lubricant may become too thick, making the bearing harder to move.

Extreme temperatures can cause the bearing and parts to expand or contract.

This leads to misalignment, vibrations, and poor performance.

Bearings may corrode more easily in extreme temperatures, especially if there is moisture or humidity.

Here is the solution for bearing corrosion resistance.

Operating beyond the temperature range can increase wear and reduce the bearing's lifespan.

This requires more frequent maintenance or replacement.

High temperature bearings, including types of high temperature bearings like ceramic bearings, high temperature steel bearings, cermet bearings, and titanium alloy bearings, are designed to operate in extreme heat conditions, typically above 120°C.

These materials are designed to withstand high temperatures without losing their strength.

They offer wear resistance and can handle temperatures up to about 250°C.

However, their performance is limited in extremely hot or demanding environments.

Ceramic materials, such as silicon nitride (Si3N4) or zirconia, are often used in high-temperature bearings.

They are known for their exceptional resistance to heat, wear, and corrosion.

Ceramic bearings can operate at temperatures well over 1000°C. This makes them ideal for extremely high-temperature environments.

Hybrid bearings combine steel and ceramic materials, typically with rings and ceramic balls.

They also offer low friction and wear resistance. They are used in applications that require high performance.

These bearings also offer moderate to high-temperature resistance, up to around 300°C.

Heat treatment processes like carburizing, induction hardening, nitriding, and tempering improve bearing durability and performance.

These processes are effective at temperatures up to 330°C. These treatments stabilize the material and enhance resistance to thermal stress, wear, and fatigue.

They ensure efficient operation in high-temperature applications.

High-temperature greases, graphite, MoS₂, and fluorinated oils are designed to withstand extreme conditions.

They are used in industries like aerospace, steel production, and chemical processing.

These lubricants reduce friction and protect against wear. They also extend the lifespan of bearings and machinery in high-heat environments.

Specialized materials like ceramics and certain alloys help maintain optimal internal clearance.

Combined with thoughtful bearing design adjustments, they prevent damage because of heat.

By addressing thermal expansion, manufacturers can extend the lifespan of bearings. This also improves the reliability of machinery operating in extreme conditions.

Standard bearings can handle temperatures up to 120°C, suitable for general use.

High-temperature bearings can withstand up to 1600°C.

Material Degradation: High temperatures (above 120°C) weaken the bearing material (like carbon or chromium steel).

Lubricant Failure: Heat breaks down the lubricant (oil or grease) inside the bearing.

Thermal Expansion Issues: Heat causes the bearing parts to expand

|

Characteristic |

High-Temperature Bearings |

Standard Bearings |

|

Common Materials |

High-carbon chrome steel (AISI 52100), ceramics (e.g., Silicon Nitride, Zirconia) |

Chrome steel (AISI 52100), stainless steel (AISI 440C), plastic, brass/bronze |

|

Temperature Resistance |

Can withstand temperatures from 180°C to 330°C, and sometimes higher |

Typically withstands up to +120°C for open bearings and +80°C for sealed bearings |

|

Wear Resistance |

Materials are heat resistant, oxidation-resistant, and have high wear resistance |

Performs well under normal temperatures but may wear out quickly at high temperatures |

|

Corrosion Resistance |

Stainless steel and special alloys for enhanced corrosion resistance |

Stainless steel offers some corrosion resistance but not suited for extreme heat environments |

|

Typical Applications |

High-temperature industries, gas turbines, kilns, etc. |

Machinery, general industrial applications, and low-temperature environments |

|

Application Type |

Standard Bearings |

High-Temperature Bearings |

|

Industrial Machinery |

General-purpose machinery, conveyors, and pumps |

High-heat furnaces, kilns, and foundries |

|

Automotive |

Wheel hubs, transmissions, and engines |

Turbochargers, exhaust systems, and brakes |

|

Aerospace |

Landing gear, actuators, and control systems |

Jet engines, re-entry systems, and turbines |

|

Food Processing |

Conveyor belts, mixers, and packaging machines |

Baking ovens, fryers, and sterilization units |

|

Medical Equipment |

Scanners, dental tools, and precision devices |

Autoclaves, sterilizers, and high-heat tools |

|

Energy Sector |

Wind turbines, hydro plants, and generators |

Gas turbines, nuclear reactors, and boilers |

|

Oil & Gas |

Pumps, drilling rigs, and compressors |

High-pressure steam pipelines, refineries |

Standard bearings use traditional oils or greases, which are suitable for general machinery.

However, they may degrade under high temperatures, requiring regular lubrication and maintenance.

High temperature bearings use advanced lubricants like PTFE, WS2, or MoS2, which perform well in extreme heat and harsh environments.

These lubricants provide durability, low friction, and reduced maintenance.

This makes them ideal for industries like aerospace, steel production, and chemical reactors.

|

Lubricant Type |

Temperature Range |

Description |

|

Conventional Greases/Oils |

-30°C to 150°C (up to 200°C for synthetic) |

Common for general use, but degrade at high temperatures. |

|

PTFE (Teflon) |

-200°C to 260°C |

Low friction, heat-resistant, used in high-speed applications. |

|

WS2 (Tungsten Disulfide) |

-270°C to 700°C |

Excellent for extreme heat, low friction, and wear resistance. |

|

MoS2 (Molybdenum Disulfide) |

-200°C to 450°C |

High-load and high-temp performance, used in aerospace and automotive. |

|

Graphite |

-200°C to 450°C |

Solid lubricants for extreme heat and pressure. |

|

Silicon-Based Oils |

-60°C to 250°C |

Good for moderate to high temperatures, stable and resistant to oxidation. |

|

Synthetic Oils |

-40°C to 300°C (up to 400°C) |

High-performance oils, last longer in high temps. |

|

Fluorosilicone Oils |

-70°C to 260°C |

Used in extreme conditions like aerospace. |

Standard bearings are economical because they are made from common materials like carbon and chrome steel.

These materials are cheap and mass-produced. They come in many sizes, making them easy to find and replace.

Their simple design keeps manufacturing costs low, and regular lubricants are affordable. This makes them a cost-effective option for general machinery.

High temperature bearings are made from advanced materials like silicon nitride, zirconia, or high-temperature steels. These materials are costly to produce.

Additionally, these bearings often require custom designs to meet specific performance needs in extreme heat and harsh environments.

Standard bearings need regular maintenance and frequent lubrication to work properly.

The lubricant can wear out over time, so it needs to be replaced regularly to avoid friction and damage. Without proper maintenance, the bearings can fail faster.

High-temperature bearings need very little maintenance because they are made from durable materials that can handle extreme heat.

These bearings last longer and don’t need frequent lubrication, making them more reliable in tough conditions.

This is the highest temperature the bearing will experience during short-term or peak conditions.

Ensuring that the bearing can tolerate this temperature without failure is important.

This is especially crucial during startup, shutdown, or abnormal operating conditions.

This is the temperature at which the bearing will operate consistently during regular use.

Bearings used in high temperature environments must withstand this temperature over long periods without significant wear or degradation.

Turbines (Power Plants):

Scenario: In gas or steam turbines, the temperatures inside the turbine chambers can exceed 700°C.

Reason: Standard bearings would fail because of overheating and wear. High-temperature bearings made of materials like silicon nitride or MoS2 can withstand extreme conditions and maintain performance.

Understanding load and speed is key to choosing the right bearing. These factors affect performance, lifespan, and efficiency.

High temperatures reduce the load capacity of standard bearings.

As it gets hotter, the materials can weaken. This makes the bearing less able to handle heavy loads and increases the risk of wear or failure.

Exposure to corrosive elements, dust, or moisture can significantly harm bearings.

This can cause wear, corrosion, or lubrication failure, reducing their lifespan and effectiveness.

Bearings in such environments need to be specially designed or protected to withstand these factors.

High temperature bearings are often coated for additional protection.

These coatings help protect the bearings from corrosion, wear, and damage caused by extreme heat, moisture, and other harsh conditions.

Coatings can also improve lubrication retention and reduce friction, extending the bearing's lifespan in high temperature environments.

Choosing high temperature bearings involves a higher initial investment.

However, they offer better operational efficiency, longer lifespan, and reduced maintenance needs.

This often leads to cost savings over the long term, making them a more cost-effective option.

This is especially true in high-heat or demanding applications, even though they come with a higher upfront price.

A steel mill switched to high temperature bearings for its rolling mills and saved money in the long run.

While the bearings cost more upfront, they last longer than standard ones.

This reduces the need for frequent replacements and maintenance. This led to less downtime, lower maintenance costs, and higher efficiency.

Over three years, the mill saved 30% on maintenance, making the initial investment worthwhile.

Bearings made for high heat are built with special materials that keep their strength and performance in extreme temperatures.

These materials, like ceramics, heat-resistant steels, ceramic-metal composites, and titanium alloys, resist damage from heat, expansion, and wear.

This helps the bearings work well in hot environments such as furnaces, kilns, and engines. They stay strong, reduce friction, and last longer, even under constant heat.

Bearings need to support rapid rotation without overheating or losing precision.

They must reduce friction and ensure smooth operation to prevent wear and failure.

Bearings in turbines and compressors operate in environments where temperatures can exceed 1000°C.

They must be made from materials like ceramics or high-temperature steels.

These materials can maintain strength and performance at extreme temperatures.

The harsh conditions inside jet engines include high heat and exposure to chemicals.

These conditions require bearings that are resistant to wear, corrosion, and thermal damage.

Bearings used in chemical plants are made from materials like stainless steel, ceramics, or cermet.

These materials resist corrosion from chemicals, acids, and salts.

These bearings are designed from high temperature steels or titanium alloys.

They maintain their strength and integrity even in environments where temperatures can exceed 500°C or more.

Many bearings have seals or coatings to prevent chemicals or moisture from getting in.

These features help resist wear and corrosion.

High temperature steels are specially designed alloys. They maintain their strength, hardness, and resistance to thermal expansion even at elevated temperatures.

These steels are often used in applications where temperatures exceed the limits of regular steels.

Hybrid ceramic bearings combine ceramic balls with steel races, creating a bearing that offers the benefits of both materials.

The ceramic balls, made from silicon nitride, resist heat, corrosion, and wear. The steel races provide strength and support.

High-temperature bearings can withstand extreme heat and harsh conditions. While they are more expensive initially, they offer better durability.

Standard bearings are cheaper and work in moderate heat but require more maintenance and replacements when exposed to high temperatures.

Choosing the right bearing is key to ensuring good performance and long life. The right bearing improves efficiency, reduces maintenance, and helps the machinery last longer.

For expert guidance in selecting the ideal bearing for your needs, contact LILY Bearing today!

LILY has supplied assistance in Tesla’s create new products at the Gigafactory, a special custom slewing bearing made by Lily Bearing will soon start...

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...