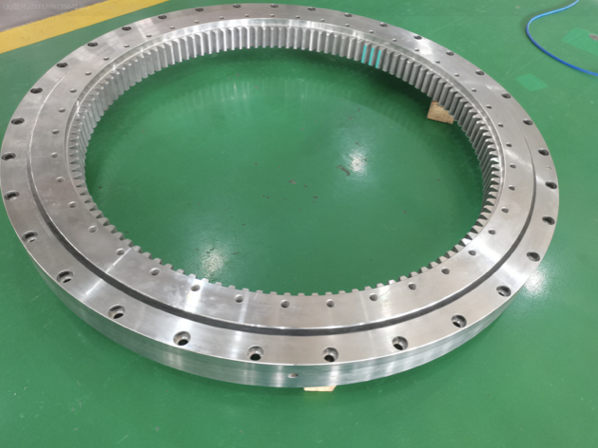

Tesla and its Gigafactory run with Lily Bearing

LILY has supplied assistance in Tesla’s create new products at the Gigafactory, a special custom slewing bearing made by Lily Bearing will soon start...

High temperature bearings are built to work well in extreme heat, where regular bearings would fail. They use heat-resistant materials like ceramics or stainless steel. Special lubricants help them stay reliable in tough conditions.

High temperature bearings are important in industries like aerospace, where they handle heat in jet engines and spacecraft. In automotive engines and exhaust systems, they keep things running smoothly. In manufacturing, they are used in processes like steel production and ovens to keep operations efficient and reduce downtime.

This blog will explain the key features of high temperature bearings and how they perform in extreme conditions. The discussion will cover their importance in industries such as aerospace, automotive, and manufacturing.

Consistent Lubrication Supply: Consistent lubrication supply ensures the bearing always has enough oil or grease. This prevents damage and helps the bearing work reliably over time.

Extended Bearing Life: Effective lubrication retention helps reduce wear and tear on the bearing. This extends its lifespan by keeping it running smoothly and efficiently.

High temperature bearings are made from strong materials like ceramics and stainless steel. This allows them to perform effectively in extreme conditions. They last longer, resist corrosion, and handle heavy loads.

Their ability to manage high speeds makes them ideal for industries like aerospace and automotive. Special lubricants and seals help them run smoothly and last even longer.

If you need bearings for tough conditions with high heat or heavy loads, high temperature bearings are a great choice. They’re built to last and keep your equipment working well in extreme environments.

For expert advice and customized solutions tailored to your needs, contact LILY Bearing today. Our team is ready to help you choose the right bearings for your specific applications.

LILY has supplied assistance in Tesla’s create new products at the Gigafactory, a special custom slewing bearing made by Lily Bearing will soon start...

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...