What is the Torque of a Slewing Bearing?

Slewing bearings play a key role in many industries. They allow things to rotate while also handling different types of loads. One important part...

High temperature bearings are important for machines that work in hot conditions. They keep things running smoothly and safely, even when the job is tough.

Understanding and optimizing load capacity helps machines work better and last longer. It also enhances their energy efficiency. This reduces downtime and costs. It also boosts productivity and reliability.

This blog explains why high temperature bearings are important. It also shows how understanding load capacity improves performance and service life.

It covers key factors that affect load capacity and tips for optimizing performance. It also highlights mistakes to avoid when choosing bearings for tough conditions. Learn how to keep your machines running smoothly and reduce downtime.

Load capacity is the maximum weight a bearing can safely support without breaking or wearing out. It keeps the bearing working well over time and extends the life of the machinery.

Static Load Rating (C₀): The Static Load Rating (C₀) is the maximum weight a bearing can handle without getting damaged. This applies when the bearing is not moving and is under a static load.

Dynamic Load Rating (C): The dynamic load rating (C) is the maximum weight a bearing can handle while rotating. This rating is based on a specified number of turns, typically 1 million rotations. It shows how well the bearing can support loads during use without wearing out or breaking.

Extreme heat can have a significant impact on bearings and their components

Load capacity is directly linked to common bearing issues like wear, misalignment, and premature failure

Here’s a comparison between lubrication-free bearings and traditional grease-lubricated bearings:

|

Feature |

Lubrication-Free Bearings |

Grease-Lubricated Bearings |

|

Lubrication |

No external lubrication required. |

Requires regular application of grease for lubrication. |

|

Maintenance |

Low maintenance, no need to replenish lubricants. |

Regular maintenance needed to ensure proper lubrication. |

|

Friction |

Reduced friction with built-in lubricating materials (e.g., graphite, PTFE). |

Lower friction, but relies on grease to maintain it. |

|

Temperature Range |

Typically can handle a wide range of temperatures without lubrication breakdown. |

Limited by grease's ability to handle high temperatures. |

|

Durability |

Generally lasts longer in clean environments but may wear faster in extreme conditions. |

Can last longer in harsh environments with proper lubrication. |

|

Applications |

Ideal for low-maintenance applications, sealed environments, or where grease isn’t suitable. |

Common in industrial machines, high-load environments, and where regular lubrication is feasible. |

|

Cost |

Higher initial cost, but lower long-term maintenance costs. |

Lower initial cost, but higher long-term maintenance costs because of grease replenishment. |

|

Environmental Impact |

More eco-friendly since no grease is used. |

May require disposal of used grease, which can be less eco-friendly. |

|

Suitability for Harsh Conditions |

Performs well in sealed or dry environments. |

Better suited for extreme or variable load and temperature conditions with proper grease. |

Contaminants, humidity, and corrosive conditions can reduce bearing efficiency and load capacity in the following ways

Here are some ways to protect bearings from contaminants, moisture, and corrosive conditions

This is the combined load that causes the same stress as the actual loads on the bearing.

P0=X⋅Fa+Y⋅Fr

This is the load capacity needed to avoid bearing damage under static conditions.

C0req=P0/f0

Key Terms You’ll See in Load Rating Tables

The load a bearing can handle while rotating, used to predict bearing life.

The load a stationary bearing can handle without being permanently deformed.

A combination of forces (radial and axial) acting on the bearing.

The number of revolutions or hours at a certain load before 90% of bearings in a group

To read load rating tables, begin by identifying your needs, such as the type of load (radial, axial, or both). Also, consider factors like operating speed and the required lifespan. Find a bearing in the table that matches your size requirements. Make sure the Dynamic Load Rating (C) is higher than your load and the Static Load Rating (C₀) can handle heavy, stationary loads.

Use the formula L10=(C/P)3 to check if the bearing life meets your needs, where P is your actual load. Also, confirm the bearing’s speed rating works for your application. Choose a bearing that fits all these factors.

Check the maximum temperature rating, speed limits, and load capacities in the manufacturer’s datasheet.

Conduct a trial run in actual operating conditions to ensure the bearing performs as expected.

Consulting manufacturers or bearing specialists for expert advice is a good idea. They can help you choose the best bearing for your specific needs and conditions.

Proper alignment and securing methods are crucial to ensure the bearing operates efficiently. They help distribute the load evenly across the bearing. This prevents unnecessary stress and extends the bearing’s lifespan.

Leave enough space between the bearing and its housing during installation. This enables the bearing to expand as it experiences increased temperature. Use bearings with extra clearance (like C3 or C4) to allow for this.

Avoid fitting bearings too tightly during installation. Consider using materials or coatings that can withstand high temperatures without deforming.

Running-in new bearings enhances their performance and ensures smoother operation. Start with a light load to let the parts adjust and reduce friction. Slowly increase the load while checking the temperature and noise.

Make sure the bearing is properly lubricated to avoid wear and overheating. This process helps the bearing last longer and work efficiently.

Regular inspections are key to monitoring load conditions and preventing overload. Check the bearing for signs of wear, unusual noise, or temperature changes.

Ensure it’s still handling the correct load, and adjust if needed. Regularly lubricate the bearing and clean it to maintain proper function. Early detection of problems can help prevent damage and extend the bearing’s life.

For tough applications, choose bearings with advanced features like graphite lubrication or strong materials. Graphite lubrication works well in high temperatures and reduces friction. Bearings made from tough materials like ceramic or strong alloys last longer and resist wear, corrosion, and heavy loads. These bearings are great for extreme conditions, providing reliable performance.

SKF offers bearings with graphite lubrication, ideal for high temperatures and reducing friction. They offer bearings made from durable materials such as ceramic and high-strength alloys. These materials are resistant to wear, corrosion, and can withstand heavy loads. These advanced features make SKF bearings perfect for extreme conditions, ensuring reliable and long-lasting performance.

Neglecting factors like heat, contaminants, and load misalignments can lead to bearing failure. High temperatures can degrade bearings if they aren't designed for heat resistance.

Exposure to contaminants like dirt or moisture can cause wear and corrosion. Misalignments in load distribution can put extra stress on the bearing, shortening its lifespan. Always consider these factors to ensure proper bearing selection and avoid costly damage.

Underestimating or overloading bearings can cause serious problems. Overloading can cause quick wear and high friction. This may lead to overheating, damaging the bearing.

Underestimating the load can make the bearing work inefficiently, reducing its lifespan. Both can result in failure, causing costly repairs and equipment damage. Always choose the right bearing for the load to avoid these issues.

Neglecting maintenance can make bearings wear out faster and lose their ability to handle loads. Without proper care, things like poor lubrication or dirt can cause damage. This leads to unexpected downtime for repairs, which increases costs. Regular maintenance helps bearings last longer and keeps them working smoothly.

In a steel manufacturing plant, SKF high temperature bearings were installed in conveyor systems. These systems were exposed to extreme heat and heavy loads.

By switching to SKF bearings, the plant improved load handling and reduced wear. This resulted in a 30% increase in uptime and a 25% reduction in maintenance costs. Fewer bearing failures and less downtime for repairs contributed to these improvements.

The static load capacity is the most weight a bearing can support when it is not moving. The dynamic load capacity is the most weight a bearing can handle while it is moving without getting damaged.

To calculate the equivalent static load for bearings, combine the radial load (Fr) and axial load (Fa). Use this formula:

P0=X0⋅Fr2+Y0⋅Fa

Where:

P0= Equivalent static load (N or lbf)

Fr= Radial load (N or lbf)

Fa= Axial load (N or lbf)

X0= Radial load factor (from bearing tables)

Y0= Axial load factor (from bearing tables)

The best materials for high temperature bearings include ceramic, such as Silicon Nitride, for excellent heat resistance. Stainless steel or titanium are also ideal for their strong performance in high-heat conditions. Chrome steel and carbon-graphite are also good options for durability and wear resistance.

Understanding the load capacity of high temperature bearings is important to ensure they work reliably. It also helps prevent them from failing too soon. Optimizing this helps the bearings last longer in tough conditions.

Choosing the right bearing for your needs is important to keep things running smoothly. Regular maintenance helps the bearing last longer. Following the manufacturer’s guidelines ensures it works properly and avoids problems.

To choose the right bearing for your needs, explore our range of high-quality products. You can also contact our experts for personalized recommendations. Let us help you find the perfect solution to optimize your equipment’s performance!

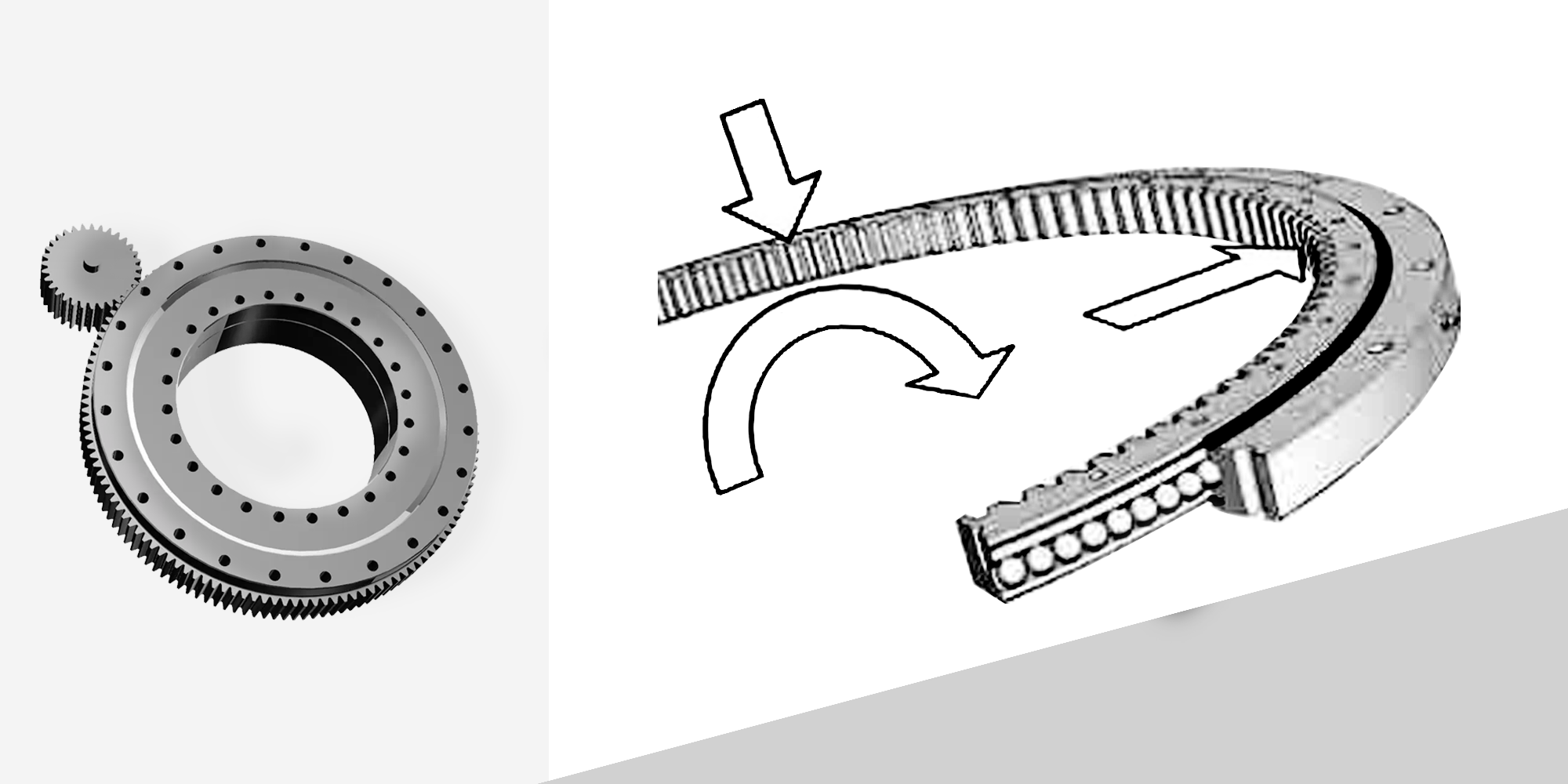

Slewing bearings play a key role in many industries. They allow things to rotate while also handling different types of loads. One important part...

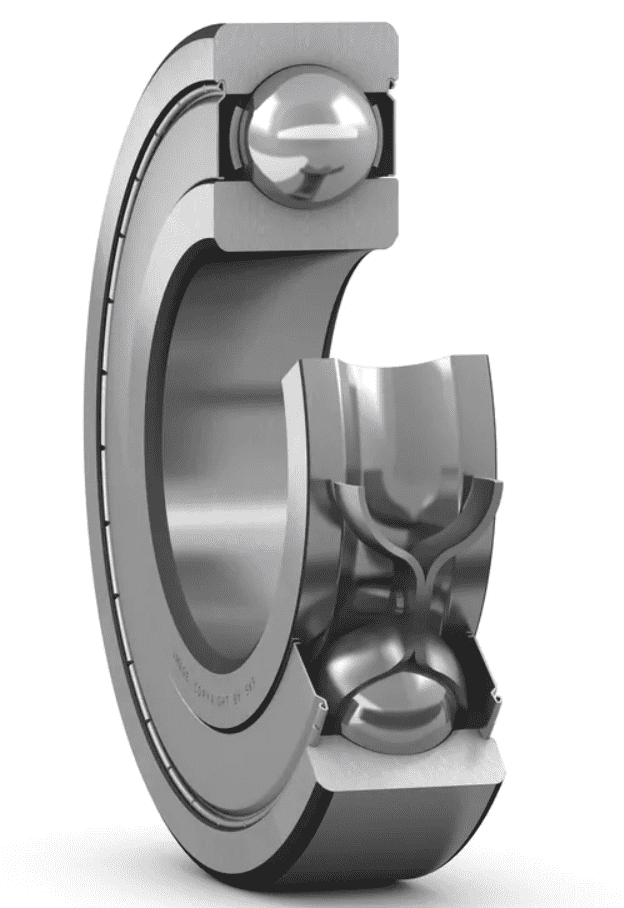

Introduction to Ball Bearings Ball bearings are parts that help things move more smoothly by reducing friction between moving parts. They have two...

Low temperature bearings, also known as cryogenic bearings, are designed to operate in extreme low temperature environments ranging from minus 40...