The Advantages And Disadvantages Of Full Complement Bearings

Full complement bearings are often overlooked in the assembly of bearings. Unlike rubber seal, steel seal, open type, and UG bearings that we are...

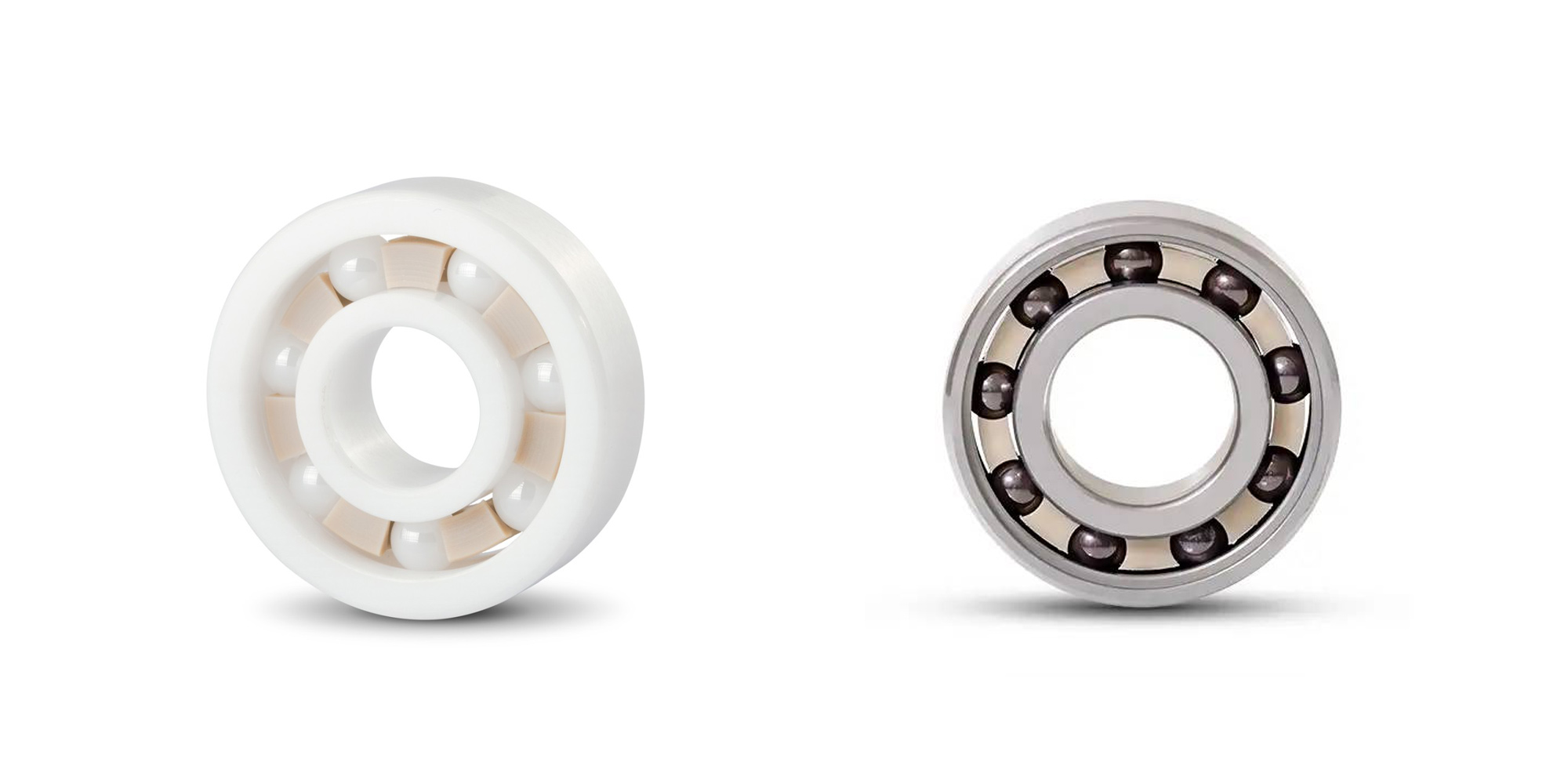

Ceramic bearings are a type of bearing that uses ceramic materials either partially or fully.

They are an alternative to traditional steel bearings. They are designed to reduce friction and support motion in various machines and devices.

This blog will look at the key differences between full ceramic bearings and hybrid ceramic bearings. We will focus on four main areas: materials, performance, applications, and maintenance.

Choosing the right bearing is important for getting the superior performance and lifespan in any application. Factors like speed, load, temperature, and durability matter a lot.

For instance, high-speed applications need bearings that reduce friction, while heavy loads require stronger, more durable bearings.

Also, if a machine runs at extreme temperatures, you need bearings made from materials that can handle the heat.

By considering these factors, you can choose the best bearing type for your needs. This will help improve the efficiency and reliability of your equipment.

Ceramic materials, like silicon nitride or zirconia, are harder, lighter, and better at handling heat and corrosion than steel.

Full ceramic bearings are resistant to rust and chemical damage. Unlike metal bearings, they won’t corrode when exposed to water or harsh chemicals.

This makes full ceramic bearings perfect for use in industries like food processing or chemical manufacturing.

Full ceramic bearings can handle much higher temperatures than regular metal bearings without losing performance.

They remain durable and perform well even under high temperatures.

This makes full ceramic bearings suitable for high-speed engines and aerospace applications.

Full ceramic bearings can work without any grease or oil. Their low friction means they don’t need lubrication to operate well.

This reduces maintenance and prevents lubricant pollution. As a result, full ceramic bearings are ideal for precise uses in medical devices and electronics.

Full ceramic bearings are highly hard, but they are also more brittle than metal bearings.

This means full ceramic bearings can crack or break if exposed to sudden impacts or heavy shocks.

In situations where strong forces are common, full ceramic bearings may not be the best choice.

Full ceramic bearings usually can’t handle as much speed. They also can't support heavy loads like hybrid ceramic or metal bearings.

While full ceramic bearings perform well in high temperatures, they might not be suitable for extremely fast or heavy-duty applications. This can limit where they can be used effectively.

Hybrid ceramic bearings are designed with a combination of materials to leverage the strengths of both ceramics and metals.

Specifically, hybrid ceramic ball bearings consist of stainless steel rings combined with ceramic balls, typically made from silicon nitride (Si₃N₄).

Hybrid ceramic bearings can run at higher speeds because the ceramic balls reduce friction.

This makes hybrid ceramic bearings ideal for motors and turbines.

Hybrid ceramic bearings are highly durable because the hard ceramic balls and strong steel rings resist wear.

This results in a longer service life and lower maintenance costs.

Hybrid ceramic bearings can better absorb shock loads, thanks to the toughness of the steel rings.

This makes hybrid ceramic bearings suitable for demanding environments like construction.

The ceramic balls act as electrical insulators, protecting against electrical currents.

This feature is useful in electric motors and helps prevent damage.

Hybrid ceramic bearings are less resistant to corrosion because of their steel rings.

In contrast, full ceramic bearings offer better corrosion resistance. The ceramic balls are highly resistant to rust and chemicals.

However, the steel components can corrode when exposed to moisture or harsh environments.

This means that hybrid ceramic bearings may require more maintenance or special coatings to improve their corrosion resistance.

As a result, their use may be limited in applications where exposure to water or chemicals is common.

Hybrid ceramic bearings require lubrication to prevent wear on the steel rings.

This is especially important in high-speed or high-load applications, where the friction can increase significantly.

Proper lubrication helps to ensure smooth operation and prolongs the lifespan of the bearings by reducing heat and wear.

|

Feature |

Full Ceramic Bearings |

Hybrid Ceramic Bearings |

|

Material |

Made entirely of ceramic (typically Silicon Nitride or Zirconia) |

Ceramic balls (usually Silicon Nitride) with steel rings |

|

Speed Capability |

Extremely high-speed operation (up to 150,000 RPM in some cases) |

High-speed, but slightly lower than full ceramics (up to 60,000 RPM) |

|

Load Capability |

Limited load capacity compared to hybrid ceramic bearings due to lack of steel components |

Higher load capacity due to steel rings, offering better strength under heavy loads |

|

Durability |

Extremely durable, corrosion-resistant, and wear-resistant |

Durable but less wear-resistant than full ceramics due to steel components |

|

Operating Temperature |

Can handle very high temperatures (up to 1,000°C, depending on ceramic material) |

Generally operates in lower temperature ranges (up to ~200°C) due to steel rings |

|

Friction |

Very low friction, which leads to higher efficiency and speed |

Lower friction than steel bearings, but slightly higher than full ceramics |

|

Cost |

Higher cost due to full ceramic construction |

More affordable than full ceramic bearings due to the combination of ceramic and steel |

|

Feature |

Full Ceramic Bearings |

Hybrid Ceramic Bearings |

|

Lifespan |

Long lifespan in corrosive environments; less durable under shock loads |

Generally longer lifespan in high-speed applications; durable under high loads |

|

Corrosion Resistance |

Excellent corrosion resistance; suitable for harsh chemicals |

Moderate corrosion resistance; steel rings can rust without protection |

Hybrid ceramic bearings are widely used in the electric motors of high-performance vehicles. This includes those found in Formula E racing cars.

These vehicles demand exceptional speed, efficiency, and reliability to compete at the highest levels.

|

Factor |

Full Ceramic Bearings |

Hybrid Ceramic Bearings |

|

Cost |

Higher cost due to the use of 100% ceramic material |

Lower cost due to the combination of ceramic balls and steel rings |

|

Performance (Speed) |

Very high speed capability, with minimal friction |

High speed, but slightly lower than full ceramics |

When choosing the right bearing, whether it's a full ceramic bearing or a hybrid ceramic bearing, it's important to consider your specific requirements.

We recommend consulting with LILY Bearing, we can offer you helpful advice.

Full complement bearings are often overlooked in the assembly of bearings. Unlike rubber seal, steel seal, open type, and UG bearings that we are...

Curious about maintaining ceramic bearings? Questions like “What makes ceramic bearings better?”, "What can I use to clean ceramic bearings?" or...

Dental bearings, though small, are vital in dental handpieces, crucial for effective and efficient procedures. These bearings offer significant...