Double-Direction Thrust Ball Bearings Promoted Water Pumps to Run Well

When you turn on the tap, have you ever wondered how the tap water you use every day reaches the water pipes in your home? Actually, this should be...

Bearings are crucial components in the mechanical world, helping rotating equipment run smoothly and efficiently.

Preloading a bearing is an engineering strategy designed to optimize its performance.

But what exactly is bearing preload, and why is it so important?

This blog post covers the basics of bearing preload.

It discusses the benefits and effects of bearing preload on the lifespan and performance of bearings in various applications.

Before we delve into the specifics of bearing preload, let's clarify what we mean by bearing load.

Bearing load refers to the forces exerted on a bearing during operation.

These forces can be static or dynamic.

The load affects how the bearing operates, its service life, and its performance.

Bearings can handle specific loads, exceeding these limits can cause them to break down sooner.

Bearing preload is a force acting between the rolling elements and bearing rings.

It operates without any external load and acts as negative internal clearance within the bearing.

Bearing preload can eliminate the clearance in standard ball bearings , such as the 608 Bearing.

Most radial ball bearings have built-in bearing clearance for free movement.

Without preload, this space can cause the rolling elements to slide instead of roll and may lead to race misalignment.

Preloading keeps the bearing parts in contact, removing any looseness and making the structure more rigid.

It offers several advantages, such as:

By preloading a bearing, you effectively increase its rigidity.

This is particularly beneficial in applications where precise movements are crucial.

A preloaded bearing keeps a more stable position, improving the system's overall accuracy.

Vibrations can be detrimental to bearing performance.

Preloading reduces vibrations by keeping the bearing components in constant contact, which lowers noise and extends the machinery's lifespan.

Preloading helps distribute the load more evenly across the rolling elements.

This uniform distribution can prevent uneven wear and tear, leading to a more reliable and longer-lasting bearing.

While bearing preloading is beneficial, it's not without its challenges.

Incorrect preload can lead to issues such as increased heat generation, reduced efficiency, and premature failure.

Choosing the right preload for a bearing system is crucial.

It depends on factors like bearing size, required stiffness, torque, lifespan, and loading conditions.

Preload Scenarios:

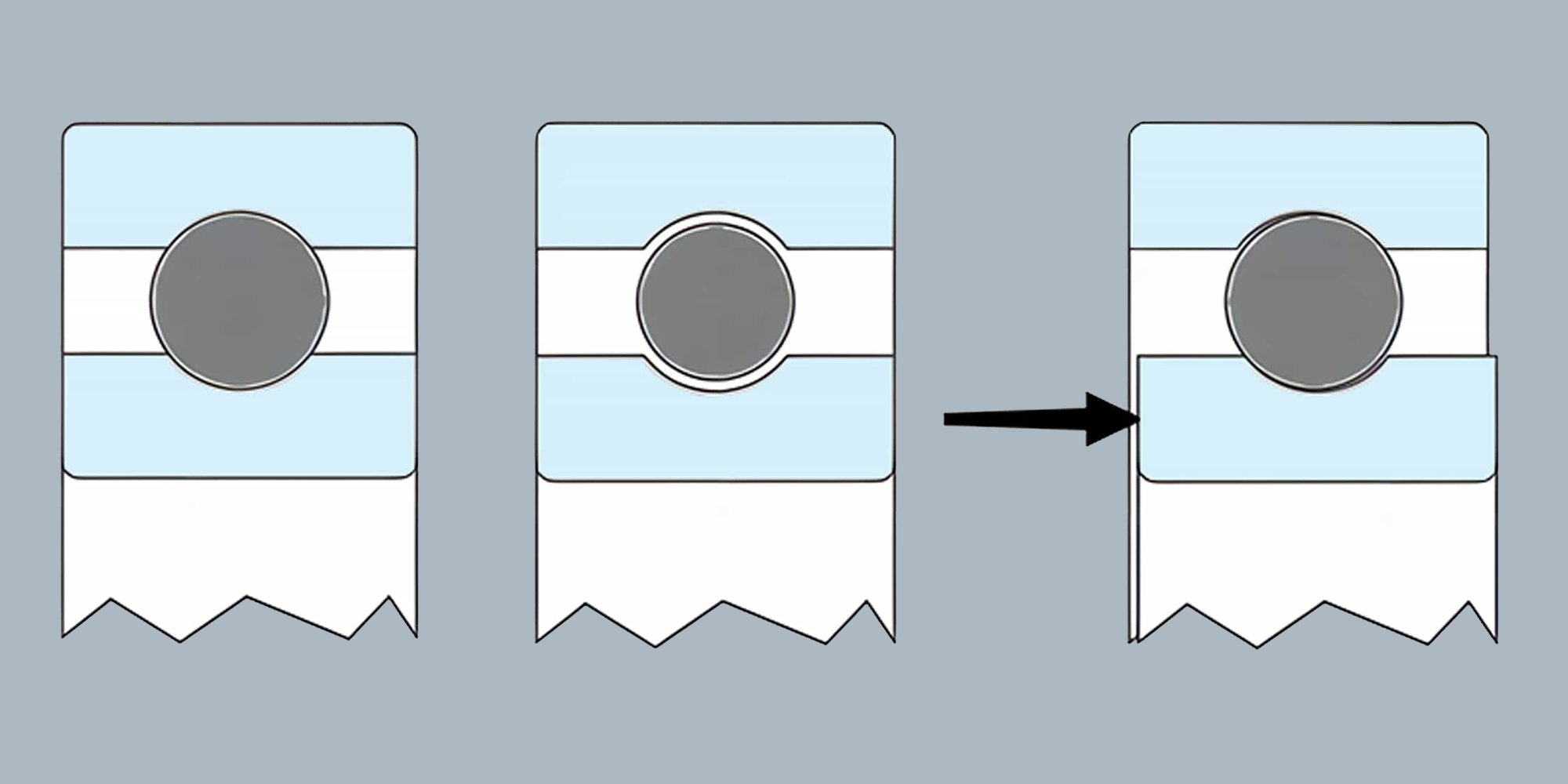

Fig 1. No play or interference fit. All rolling elements are loaded, causing excessive wear and heat.

Fig 2. Standard play in the free state. Low rigidity, with rolling elements sliding or skidding.

Fig 3. Proper preload applied. Ensures system rigidity, reduced vibration, and longer bearing life.

Applying the correct preload is essential for optimal performance, providing system rigidity, reduced vibration, and extended bearing life.

Be precise when preloading a bearing because both under-preloading and over-preloading can cause problems.

Here are the methods for preloading bearings:

Achieve fixed preload by manufacturing the bearing with a predetermined amount of force applied internally.

Create this preload by slightly offsetting the dimensions of the races or by using springs.

Use fixed preload in applications where operating conditions are relatively stable and predictable.

Adjust preload to suit various needs, offering flexibility for different purposes.

Achieve this adjustment through techniques such as using shims, threaded nuts, or wave springs.

Adjustable preload is ideal for situations where operating conditions are variable or not well known in advance.

Applicable to cylindrical roller bearings due to their design.

Fig 4 Preload cylindrical roller bearings radially

For tapered bore bearings:

Use internal clearance gauges to set preload accurately.

Angular contact ball bearings require preload to ensure constant contact between the balls and raceways. This can be achieved through:

Axial Displacement:

Fig 5 Back to Back

Fig 6 Face to Face

Spring Preload:

Consult engineering services for optimal preload methods to ensure bearing performance and longevity.

Preloading bearings is a common practice in many industries.

Preload is essential to prevent skidding in high-speed applications.

This is especially true during rapid starts, stops, or under light or no-load conditions.

Bearing preload is also crucial for increasing system rigidity and positional accuracy in most high-precision applications.

Here are a few applications where bearing preload is essential:

Adjust the wheel bearings before using cars.

This process ensures that the wheels can turn smoothly and support the weight of the vehicle without wearing out quickly.

The aerospace industry requires extremely high levels of precision and rigidity.

Bearings in airplanes and spaceships are pre-set to comply with these rigorous demands.

Bearings for machine tool spindles use bearing preload for better accuracy and stability, resulting in high-quality, precisely made parts.

Preload on bearings is a crucial factor to consider in any application that utilizes bearings.

Engineers and technicians can improve machinery efficiency and longevity by understanding bearing preload and its impact on bearing performance.

Whether you're working with fixed or adjustable preload, it's crucial to apply the correct amount to avoid potential complications.

Proper bearing preloading improves your equipment and prevents issues.

At LILY Bearing, we offer a wide range of bearings to fit any application.

When you turn on the tap, have you ever wondered how the tap water you use every day reaches the water pipes in your home? Actually, this should be...

Bearing speed is vital for machinery efficiency and durability. Its capacity is often measured by its operating temperature. Excessive friction heat...

As a main bearing supplier, Lily Bearing is well-known for its high-quality bearings, professionalism as well as top-torch services. Undoubtedly, s...