What Is a Ball Bearing?

What is a ball bearing? A ball bearing is a type of rolling-element bearing that utilizes balls to maintain separation between the bearing races. The...

7 min read

Erik : Aug 26, 2025 10:59:32 PM

Bearings play a critical role in the health of industrial machinery, ensuring operations run without a hitch. The processes of 'how to install a bearing' and 'how to remove a bearing' are far more than routine maintenance; they are pivotal steps that can markedly boost a machine's performance and longevity.

This guide focuses on the precision and safety needed to execute these tasks effectively. Dive in as we unpack expert strategies and best practices to maintain the robustness of your machinery.

Before starting industrial bearing installation, prioritizing safety and preparation is crucial for a smooth, risk-free process. Having the right safety gear and a prepped workspace and tools reduces accidents and boosts efficiency.

Understanding how to install a bearing correctly is pivotal for maintaining the efficiency and durability of industrial equipment. This section offers a comprehensive step-by-step approach, detailing both press fitting and shrink fitting techniques, and delves into the specifics of fitting various types of bearings, including wheel bearings and those subjected to radial loads.

Preparation: Ensure the workspace is clean. Gather all necessary tools and safety equipment. Thoroughly inspect bearings, shafts, and housings for any signs of damage or contamination.

Press-fitting is a prevalent technique for installing bearings, particularly favored for its precision in ensuring a snug fit for both small and larger bearings. This method revolves around the principle of securing the bearing's inner race tightly against the shaft, while the outer race may have a looser association with the housing bore. This method applies axial force, ensuring that the rolling elements are correctly positioned.

Here’s an amalgamated approach:

Bearing Press Fitting Procedure - Inner Ring

Preparation and Positioning:

Press-Fitting for Small Bearings:

Employ an arbor press to slowly push the bearing onto the shaft until the inner ring aligns flush with the shaft's shoulder. This method is ideal for small bearings with minimally tight fits and is often used during bearing replacement.

Handling Larger Bearings:

Diagram of Simultaneous Press Fitting Procedure for Bearings

Dealing with Non-separable and Separable Bearings:

Specifics for Snug Fit:

To achieve a tight fit between the bearing rings and their respective mounting surfaces (shaft and housing), ensure that the mounting sleeve used can press both the inner and outer ring ends simultaneously. This ensures a uniform force distribution and prevents damage to the bearing surfaces, particularly important in gearboxes and electric motors.

Press fitting for Cylindrical Bore Bearings:

Assembly Casing Usage:

When the outer ring requires a tight fit, press the bearing into its housing first, utilizing an assembly casing with a slightly smaller diameter than the housing hole. For the inner ring, use a soft metal casing (such as copper or mild steel) to cushion and protect the end face during the press-fitting process.

Stages of Precision Press-Fitting for Bearing Installation

Shrink fitting is a favored method for mounting large bearings without excessive force, using heat to expand the bearing before installation.

Precautions for Shrink Fits:

Post-Installation:

Expect bearings to contract both axially and radially as they cool. Ensure they are pressed against the shaft shoulder to prevent any gaps. Use appropriate locating techniques for accurate placement.

Advancements in bearing installation, such as induction heaters, offer efficient and precise methods for fitting bearings. These techniques underscore the significance of temperature control during the installation process.

Using these methods, especially induction heating, aligns with professional standards for "how to install a bearing," ensuring that bearings are installed under optimal conditions to extend their service life and enhance machinery performance.

In the realm of industrial maintenance, knowing how to remove a bearing is as critical as installation. The choice of removal method must consider the bearing's size, location, and the machinery's design. Understanding the terms associated with bearing removal is crucial for proper disassembly and maintenance.

The most reliable method for various sizes and types of bearings, including ball bearings and roller bearings. It ensures even force distribution, minimizing the risk of damage.

Advantages:

Key Advantages:

Considerations and Risks:

Risks:

For further advice on how to remove bearings, click here, please!

Common mistakes during the removal process include:

Adhering to best practices in bearing removal not only ensures the safety of personnel but also protects machinery from unnecessary harm, maintaining operational efficiency and reducing downtime.

In summary, mastering the techniques of 'how to install a bearing' and 'how to remove a bearing' is crucial for the optimal performance and extended life of your equipment. Always prioritize precision and safety, and for further insights, stay tuned to our blog.

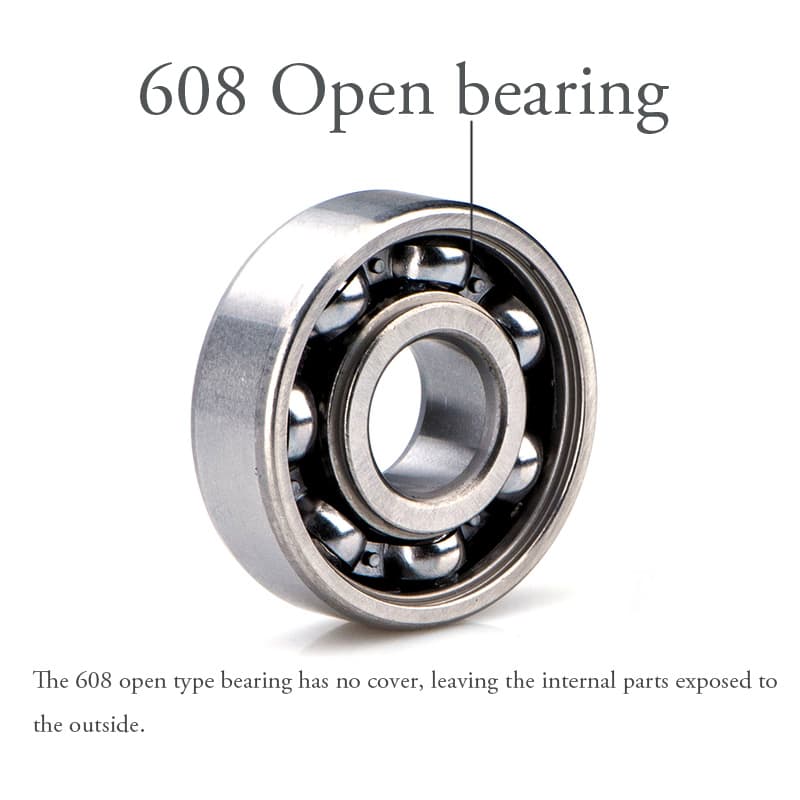

What is a ball bearing? A ball bearing is a type of rolling-element bearing that utilizes balls to maintain separation between the bearing races. The...

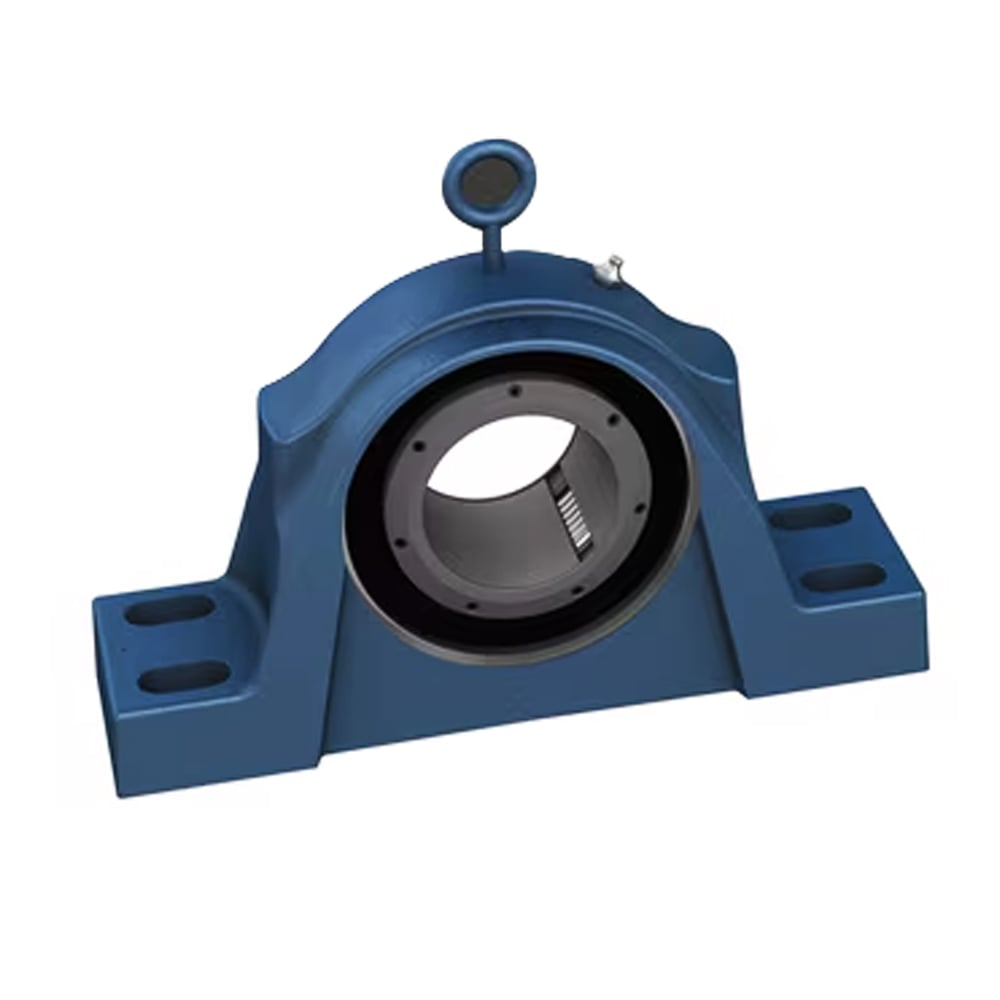

In the world of machinery, mounted bearings play a pivotal role. They are integral to the smooth operation of various equipment across industries....

Needle bearings are a unique type of rolling-element bearing. They use long, thin cylindrical rollers, offering a high length-to-diameter ratio. ...