Slewing Bearing and Jib Crane Bearing Guide

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

4 min read

Goodenough Lu

:

Aug 27, 2025 10:57:53 PM

Crane slewing bearings are essential parts that let cranes make their full 360-degree turns. This ability is crucial for handling various lifting jobs with ease. These bearings are designed to handle the crane's complex movements, including moment thrust and radial motion, and tilting, and they can also bear a lot of weight.

This blog post takes a closer look at the main features, advantages, and applications of crane slewing bearings. It helps you grasp just how crucial these bearings are for keeping cranes and other medium to heavy duty machinery up and running smoothly.

Crane slewing bearings are specialized parts that enable 360-degree rotation between the undercarriage and upper structure of cranes. They're crucial for the crane's mobility, enabling it to cover a wide area while lifting.

These slew ring bearings masterfully manage all sorts of loads: they deal with the horizontal side-to-side movements, the vertical loads that run along the crane's boom, and the tilting loads that come when the crane tilts to one side. Their strength and precision are key to the crane's stability and the safety of its operations.

Crane slewing bearings are crafted from strong materials like carbon and chrome steel, known for their strength and durability. These materials are tough and durable, standing up to heavy loads and minimizing wear and tear. They're perfect for bearing the weight and reducing friction.

The hardening process further enhances these properties, providing a tough core and a hard, wear-resistant surface.

These specially made custom-designed are key to keeping cranes and other heavy-duty equipment running smoothly and reliably.

Crane slewing bearings are key to a crane's ability to make complete turns and lift heavy loads. They're built to handle the significant forces that act on a crane, including the vertical pulls (axial loads), the side-to-side pushes (radial loads), and the twisting force (torque) that can try to turn the crane.

The bearing's tilting moment capacity determines the largest weight a crane can lift and how far out it can lift that weight. This is especially important when the crane is lifting at its maximum capacity and the load is at its furthest point. In this way, these bearings make sure the crane can work safely and effectively, no matter how heavy the job.

Design and Versatility

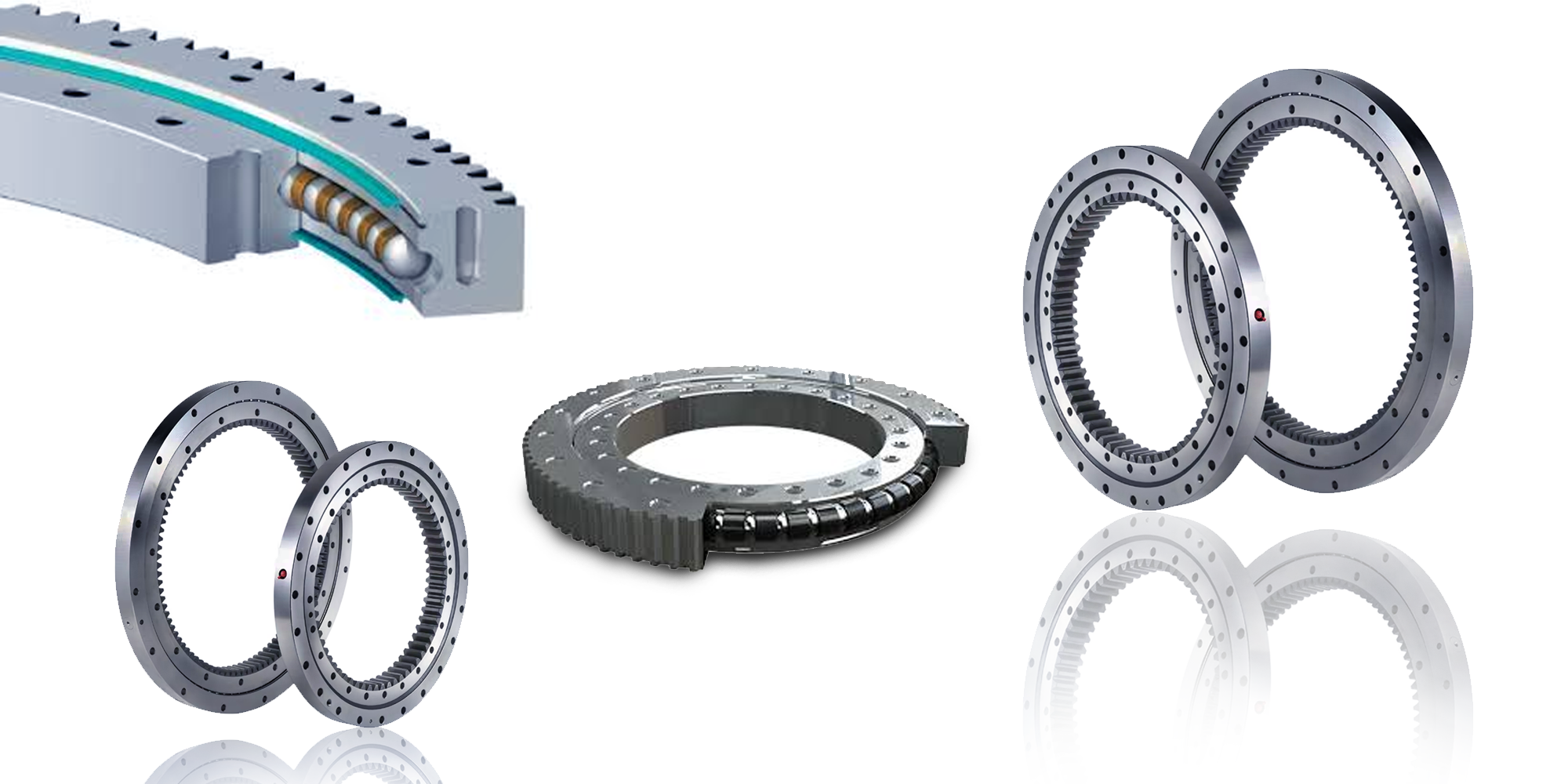

Crane slewing bearings come in several designs: single row bearings(e.g. single row four point contact ball slew bearings, thrust ball slewing rings ), double row ball bearings (e.g. eight point contact ball bearings), and cross roller bearings (e.g. cross roller slewing ring bearings).

Each type has its own unique strengths and performance traits, as described below:

For certain crane jobs, we can specially design these bearings by adding internal and external gears.

The choice of gear type depends on factors like gear static strength, resistance to pitting, gear fatigue, and the gear/pinion interface.

Low friction designs reduce wear and tear, ensuring components last longer with minimal energy loss.

Precise seals keep out dirt, which help protect the internal mechanisms and makes sure your crane keeps working well for a long time.

The use of 42CrMo4 steel, known for its strength and toughness, is ideal for withstanding the rigors of heavy loads and harsh conditions.

Gear hardening treatments are crucial for enhancing the surface hardness of gears. This special treatment helps gears last longer, especially when they're working in tough conditions. These treatments make the gears more resistant to wear, damage, and bending. This way, the gears can be reliable with longer service life in the face of extreme use.

Precisely engineered slewing bearings let cranes rotate smoothly, making sure that lifting is both safe and spot-on. A deep-groove gothic arch raceway provides four points of contact with the balls, so that the bearing simultaneously supports radial, axial and moment loads.

By keeping friction low and alignment perfect, these bearings reduce wear and tear, which means the crane lasts longer. Besides, they keep the load steady as it moves, which is super important for accurate positioning.

Slewing bearings can handle the rigors of heavy-duty cranes and harsh environments like construction sites. Crane slewing bearings feature tough materials such as carbon steel and chrome steel, which are known for their strength and durability.

These materials are super strong and don't wear out easily. That's really important for cranes because they have to handle heavy loads and demanding conditions all the time.

Keeping the bearings well-lubricated is key to keeping the moving bearing parts, such as raceways and gears of the bearings in good state. Factors like load, temperature, speed, and vibration all play a part in picking the right kind of lubricant. The right lubricant helps the bearings run smoothly and effectively, even in challenging environments.

Keeping up with routine care, like greasing and checking bolt torque, can greatly extend the life of a crane's rotating parts. This helps save money on heavy-duty crane jobs because it means reduced frequency of replacements and maintenance.

Applications of Crane Slewing Bearings

Slewing bearings are what allow tower cranes, mobile cranes, and cranes on trucks spin all the way around and handle heavy loads. They're a key part that makes these cranes work smoothly. How well they perform is key to the efficiency and safety of construction projects.

In offshore platforms and marine cranes, slewing bearings are strong enough and able to resist corrosion. They can handle the tough conditions and heavy lifting that's common in offshore work.

In mining cranes and large machinery such as dragline excavators, slewing bearings play a pivotal role. They are durable with high load capacities. That's really important for digging up minerals from the earth and moving them around quickly and effectively.

High-pressure grease is vital for slewing ring performance, preventing spalling, friction, and wear. It evenly distributes load pressure, reducing stress concentrations that cause spalling.

The grease also acts as a barrier, minimizing metal-to-metal contact, which decreases friction and wear. Keeping the crane well-greased helps it run smoothly, lasts longer, and stays dependable even under tough conditions.

Torque checks and proper bolt tightening are crucial for crane stability and performance. They prevent loosening caused by vibrations, and spread out the weight so the crane doesn't get stressed. This help maintain component alignment and reduce wear. It also enhances safety, optimize performance, and extend the crane's lifespan, which ultimately save maintenance costs.

Monitoring equipment's condition is crucial for keeping things running smoothly and for a long time. By doing regular checks and ensuring grease quality, you can prevent unexpected failures. Spotting signs of wear early on lets you fix things before they get worse, which saves money and maximizing efficiency.

Crane Slewing bearings are the heart of a crane's ability to lift and move loads with care and accuracy. Opting for top-quality crane slew bearings and keeping up with routine maintenance are simple steps that go a long way in keeping your crane safe and efficient. If your crane faces special lifting challenges or works in a unique setting, it's a smart move to get in touch with manufacturers. They can craft bespoke solutions to fit your crane's needs perfectly.

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

Turntable bearings are crucial in many fields like construction and robotics. They make sure that equipment can rotate smoothly and steadily. These...

Slewing bearings, also known as slew bearing or slewing ring bearings, facilitate pivotal movement in machinery, handling axial, radial, and moment...