What Are Needle Bearings Used For?

Needle bearings are a unique type of rolling-element bearing. They use long, thin cylindrical rollers, offering a high length-to-diameter ratio. ...

Industrial bearings are integral components in a myriad of machinery. They reduce friction between moving parts and assist in carrying loads. A vital aspect of these bearings is their bore diameter. It isn’t merely about knowing the measurements for replacements. The bore diameter signifies how the bearing will perform, especially concerning the shaft it supports.

Bore diameter, often termed the inner diameter or ID, is central to bearing functionality. It determines the bearing's inner hollow size, crucial for its interaction with the shaft.

The fit between the bore diameter and the shaft can be classified as:

Precision in measuring the bore diameter is vital. Errors can lead to misalignment, inefficiencies, and premature bearing wear, emphasizing the importance of accuracy for optimal machinery performance.

Precision plays a paramount role when measuring the bore diameter. The bearing's performance, fit on the shaft, and longevity are all contingent on this accuracy. Even the slightest discrepancy in measurement can induce misalignment or lead to inefficiencies, potentially resulting in premature equipment wear or failures.

In terms of tools, while some might resort to rulers for a quick gauge, they lack the accuracy essential for critical applications. Rulers can introduce errors, especially for minute measurements. A more reliable alternative is the digital Vernier caliper, a precision tool designed to gauge internal and external distances with far greater accuracy. Its readings are dependable to the extent of plus or minus 0.02 mm, making it an industry-favored choice.

Step-by-step guide to measuring bore diameter with Vernier calipers:

Incorporating meticulous measuring practices with suitable tools ensures the accurate determination of bore diameter, which is foundational for optimal bearing performance.

The bearing bore size is influenced by several key factors:

Understanding these factors is essential for the optimal performance and longevity of the bearing and the machinery it supports.

In the realm of bearing measurements, while tools like Vernier calipers provide commendable accuracy, there are even more precise instruments that professionals turn to, such as:

Using such tools not only helps in achieving tighter manufacturing tolerances but also ensures consistency in production. Also, embracing these advanced techniques is testament to a manufacturer's commitment to quality and the ongoing pursuit of engineering excellence.

Click “How to Measure a Bearing” to learn more information.

Bearings are crucial for machinery, with the bore diameter playing a central role in their functionality. However, selecting a bearing goes beyond just this dimension.

Shields and Seals: Protecting from contaminants . For more details, see Shielded Vs Sealed Bearings.Flanges: Aiding in positioning.

Material: Influencing durability and resistanceLubrication: Determining bearing friction and wear rates.

Expertise in Selection: Bearing selection is a nuanced process considering the environment, bearing loads, bearing speed, and more. Lily-Bearing's professionals guide users to the right choices, balancing technical specifications with practical needs.

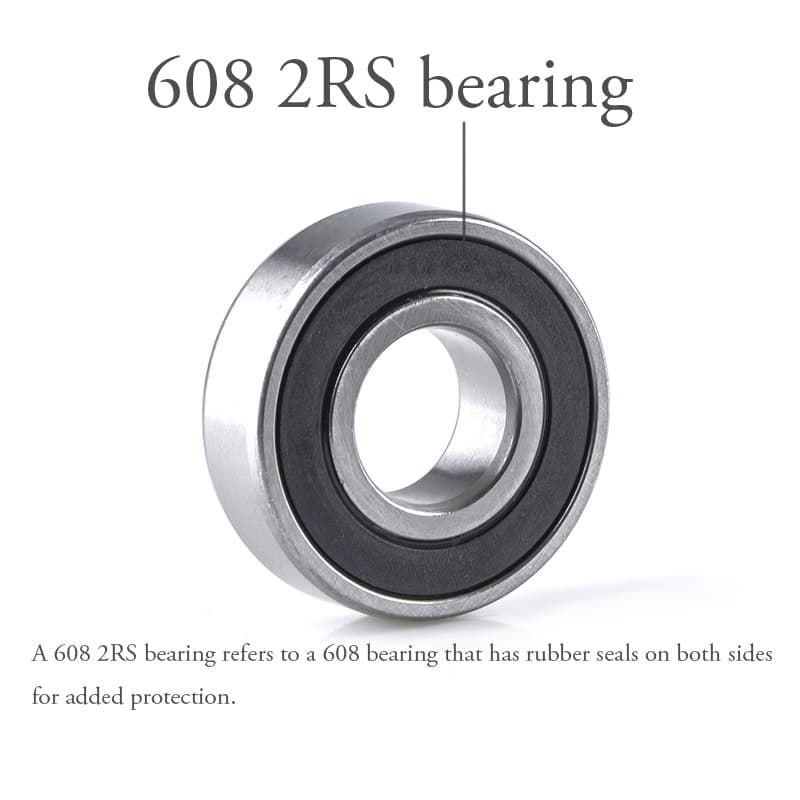

In summary, while bore diameter is essential, choosing the appropriate bearing requires a holistic approach, considering various dimensions and features for optimal machinery performance, for example, the 608 Metric Ball Bearing is designed with a precise bore diameter, making it ideal for high-speed and precision equipment where accurate measurements are crucial.

Understanding the bore diameter is not merely about replacing a bearing. It's about ensuring optimal operations, minimizing wear and tear, and maximizing longevity. Accurate bore size measurements provide insights that can be pivotal for various industries. So the next time you ponder over the bore size meaning or how to measure it, remember that precision can make a world of difference.

Needle bearings are a unique type of rolling-element bearing. They use long, thin cylindrical rollers, offering a high length-to-diameter ratio. ...

Industrial bearings are essential in industrial machinery, enabling smooth operation and reducing wear for prolonged equipment life. There exists a...

Ball bearings are unsung heroes of the industrial world, playing an indispensable role in the smooth operation of machinery across a multitude of...