McGill Cam Followers for Reliability

In the industrial sector, machines that work well all the time are essential for good performance and safety. McGill cam followers are just a crucial...

Cam followers and roller followers are essential parts in machines that change spinning movements into sliding ones. These parts are essential in many different uses, such as industrial automation to power generation.

This article aims to help you understand cam followers and roller followers better. It will compare their features, advantages, and best applications for you to choose the right solution.

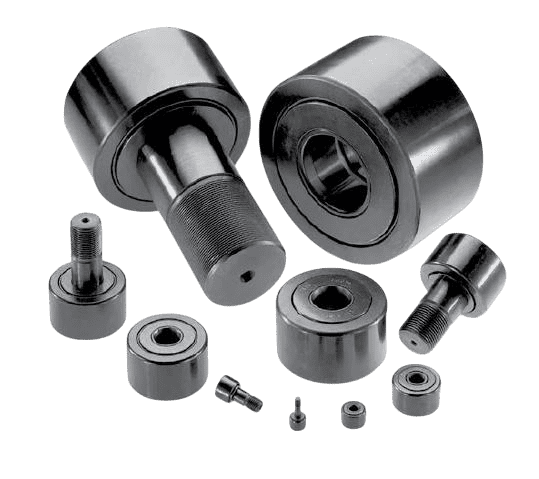

Cam followers, also known as tappets, are important parts used in machines. They take the rotary motion from a camshaft and change it into linear. They have a built-in stud, which means you can just slot them directly into the right spot without needing an extra shaft.

The primary components of a cam follower bearing include an outer ring, a stud, and needle rollers. The outer ring, available in both round (spherical) and straight (cylindrical) shapes, is where the cam pushes against. The stud is the part you attach it to, and the rollers help everything move smoothly.

Cam followers come in various types to suit different applications:

Cam followers are widely used in conveyor systems, process transfer lines, power generation, automation and so on. They work really well when you can attach them directly. For example, in heavy duty machines where you can just screw the cam follower into a flat surface. This means you don't need extra components.

Roller followers, or track rollers, work in a way that's similar to cam followers. But the difference is that they operate with an existing shaft.

They consist of an outer ring, needle rollers, and an inner ring. The outer ring engages with the cam, while the inner ring slides on the shaft, allowing for linear motion.

Roller bearings are famous for being able to handle high weight and for moving in a very accurate, straight line.

The table below compares two types of roller followers, showing how they're built and what they're usually made of.

|

Attribute |

Separable Roller Followers |

Non-Separable Roller Followers |

|

Definition |

Built to have removable inner and outer rings, making it simple to install and maintain. |

The inner ring is securely attached to the outer ring, making them one piece that doesn't come apart.

|

|

Components |

The components comprise an outer ring, an inner ring, and a needle cage. |

The components feature press-fit end plates at both sides of the inner ring, fixed to the outer ring. |

|

Inner Ring Inner Diameters (IDs) |

The dimensions span from 7 to 60 millimeters. |

The dimensions span from 5 to 50 mm. |

|

Materials |

The materials used are high-carbon steel or stainless steel, selected for their resilience and enduring quality. |

The materials are high-carbon steel or stainless steel, selected for their strength and corrosion resistance. |

Roller followers are great at turning spinning movements into linear ones. Besides, you can easily attach them to existing shafts, which makes designing and installing much simpler.

|

Attribute |

Cam Followers |

Roller Followers |

|

Mounting Style |

A built-in stud allows for direct mounting into a mating surface without the need for an additional shaft. |

Roller followers require an existing shaft for mounting and do not have a built-in stud. |

|

Ease of Installation |

You can screw them directly into a flat surface. This means you don't need extra parts like shafts or special mounting tools, making the setup process a lot simpler. This makes installation easy, especially when you have a flat surface ready for direct attachment. |

Roller followers might need a complex work to set up because you have to attach them to an existing shaft. You need to match the bore size of the follower to the shaft, which adds an extra step in the installation process. Additionally, you have to make sure to align the shaft firmly in place so that the roller follower works just right. |

Roller followers and cam followers both excel in handling high radial and shock loads because their robust design.

Roller followers, with their thicker outer rings, offer an advantage in managing heavy loads and shock resistance. The extra thickness allows them to handle heavier loads and take more impact forces. That makes them perfect for industrial jobs where they need to handle heavy load.

Cam followers are strong, but they might not handle heavy loads as well as roller followers due to their construction and material placement.

Roller followers and cam followers handle alignment issues in different ways. Roller followers usually have a special crowned outer ring that deals with small misalignments. This feature helps to keep things running smoothly and reduces wear.

Cam followers use a special crowned ring that helps to lessen the stress caused by misalignment, which is really good for making the bearings last longer.

The crowned rings in cam followers also help to keep the contact area well-oiled. In contrast, roller followers might need more frequent oiling to handle the effects of misalignment.

Cam followers are best for flat surfaces, offering easy direct mounting without the need for extra components like shafts. They're ideal for conveyors and industrial lines. Roller followers need a shaft that's already there. They work great in engines or carrier systems where they can reduce friction and stress. The choice depends on whether your setup has a flat surface or an existing shaft.

Cam followers have a handy built-in stud that makes them easy to install directly. This can save you time and means you won't need extra components.

Cam followers come in both crowned and cylindrical outer ring options. This means they can easily fit with different cam shapes and meet the needs of various tasks

Roller followers have sturdy outer rings and needle bearings that can handle a lot of weight. They're just right for tough tasks that need some extra strength.

The open bore design of roller followers is a smart featur. It indeed makes mechanical designs especially flexible by allowing easy mounting onto existing shafts.

It makes installation and integration processes simpler and easier. It also means engineers can tailor solutions without the need for additional components. All this makes things run more smoothly, performs better, and can even save money and reduce downtime in different jobs.

The choice between cam followers and roller followers often comes down to design constraints. If a flat surface is available for direct mounting, cam followers may be the better choice. If an existing shaft is present, roller followers may be more appropriate.

When choosing roller followers, environmental factors play a key role.

Temperature swings can affect performance, so heat-resistant materials might be needed.

Corrosion is a concern in environments with chemicals or saltwater, making stainless steel a popular choice for its resistance.

Contaminants like dust or dirt can cause wear, so sealed or shielded followers might be necessary to keep out debris. Each of these factors can dictate the material and design of the follower to ensure it lasts and performs well in specific conditions.

The price of each follower type depends on what they're made of, if they need extra parts like shafts, and how easy or hard they are to install.

Cam followers can save cost by eliminating the need to buy a separate shaft and the installation is simple.

Roller followers might cost more to install because they require a shaft and precision alignment. But they can be cheaper if you already have a shaft for mounting.

Choosing between cam followers and roller followers comes down to your project's needs. Think about the method of mounting, load capacity and their job in the project. Each has its own strengths and works better in different situations. When choosing between them, it's important to think about what your application actually needs.

The main difference is that cam followers have a built-in stud for direct mounting. On the other hand, roller followers require an existing shaft for mounting.

Switching between them can work in some situations. However, it depends on the specifics of your project and any design limits. If an appropriate shaft be present for attachment, you may choose roller followers instead of cam followers.

Roller followers are often the best choice for tasks that involve heavy loads. They can handle more weight and are robust in construction. However, it depends on the final precise requirements of your project.

In the industrial sector, machines that work well all the time are essential for good performance and safety. McGill cam followers are just a crucial...

Cam followers, also known as cam and followers, are crucial parts in many mechanical systems. They convert rotational motion into linear motion,...

McGill cam followers are important parts that help machines move precisely and reliably. They convert rotational motion into linear motion. Their...