What is a Cam Follower Used For?

In the vast expanse of mechanical engineering, few mechanisms are as indispensable as the cam and its accompanying cam follower. They not only...

Cam follower bearings provide smooth linear movement as the cam rotates, which minimizes wear better than sliding contacts.

This blog explores the principles of cam followers. They are important for engineers and operators.

Understanding these ideas helps stop breakdowns and makes things run better in all sorts of uses.

Cam follower bearings have robust outer rings that handle high radial loads and axial loads, keeping the system stable. They come in crowned or flat profiles. A crowned profile of the cam spreads the bearing load evenly, reducing stress, while a flat profile of the cam offers direct load support.

Cam followers use slim rollers, either needle rollers (needle-shaped rollers also used in needle bearing) or cylindrical rollers, to lower friction and handle more load. This design lets them glide smoothly and work well even when carrying a lot.

Cam followers, which include track rollers, are mounted to move along the camshaft. The track rollers within the cam followers maintain continuous contact with the cam surface. They facilitate oscillating or linear motion as the cam rotates.

The cam follower assembly is mounted on a shaft in a cam follower system, with the stud or yoke facilitating the attachment.

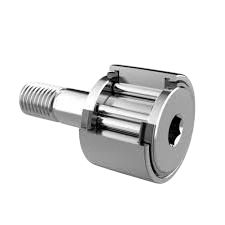

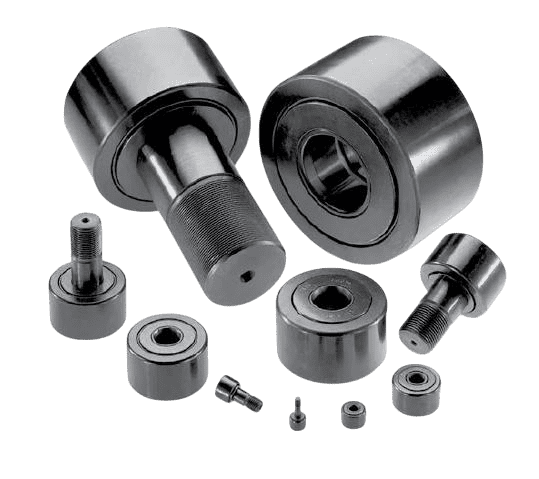

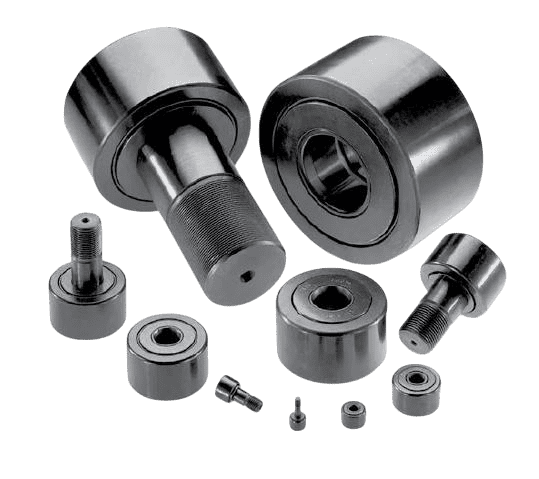

Stud-type cam followers apply a threaded stud for mounting, which is great for cantilever setups.

Yoke-type cam followers offer double-shear mounting, providing more support and stronger load transfer.

Both types of cam follower bearings offer secure attachment. However, users favor yoke designs for handling heavier loads because they distribute force more effectively.

Seals in cam followers keep out dirt and lock in bearing lubricants, which is crucial for smooth operation.

You can keep the parts well-lubricated by using grease, oil, or a maintenance-free option like C-Lube. This helps ensure that the parts will last and perform well in all kinds of conditions.

Rolling motion in cam followers trumps sliding by slashing friction and energy loss, cutting down wear and tear.

This system moves smoothly with less friction compared to sliding. It keeps operations quick and helps to prolong the life of the equipment.

A smooth ride exists in cam followers, unlike the rough-and-tumble of traditional sliding interfaces.

The outer ring of cam followers is in direct contact with the cam or track surface. This helps convert rotary motion into linear motion.

Precision machining of the cam track is vital.

It keeps steady contact, lowers wear and tear, and balances the load. This is important for keeping the follower aligned and for making the parts last longer.

Cam followers manage radial, axial, and impact loads with their strong desi gn and specialized features.

Cam followers have a strong outer edge that can deal with a lot of side pressure. Advanced features like crowned rings spread the load out smoothly, which lessens the stress on the edges when the cam follower isn't perfectly lined up or is tilted.

Cam follower bearings use strong materials. These include black oxide coating, stainless steel, and special plastics. These materials help make the bearings last longer and perform better.

Black oxide enhances wear resistance. Stainless steel wards off corrosion. And plastics offer low friction in clean environments.

All the materials ensure can follower bearings last longer and operate more reliably under various conditions.

The design of cam followers matters a lot. Choosing between stud or yoke styles affects their function. The shape of the profile of the cam, whether crowned or flat, also plays a key role in how they operate.

Stud types offer cantilever mounting, while yoke types provide double shear support for heavier loads.

Crowned profiles help spread out the load, which lessens stress.

Newer designs with eccentric collars make alignment easier. Some advanced cam followers have lifetime lubrication. This helps them work better and last longer without maintenance.

The sealing mechanisms in cam followers keep dirt out and hold lubricant in. They create a protective barrier around the bearing. They block out dirt and hold in the oil, making sure components run smoothly and wear less over time.

Lubrication systems help cam followers work well. They reduce friction, keep them cool, and stop dirt from getting in. This extends the cam followers‘ service life.

Centralized lubrication systems can simply the lubrication process and standardize it. They make the mechanical systems with cam followers more efficient, reliable and cost-effective.

Modern cam followers fit well into automated systems by providing extremely accurate and consistent motion control. They use advanced materials and designs, like needle rollers or cylindrical rollers.

These help support heavy loads with hardly any friction. Besides, they have special features like eccentric collars and different sealing options. You may customize them, making the whole system more reliable and efficient in automated settings.

New designs, like double-row rollers and thrust disk seals in cam followers, increase load capacity and speed. These features make the product stronger under heavy loads. They also protect against contaminants. This ensures it works well, even at high speeds.

Cam followers excel in high-temperature settings thanks to heat-resistant materials like stainless steel. They maintain performance and durability despite extreme heat exposure.

In clean medical equipment, where precision is crucial, cam followers also works well. They also perform reliably in corrosive environments with specialized coatings and materials designed to withstand chemical exposure.

Misalignment in cam followers can cause uneven load distribution. This can lead to more wear and a shorter lifespan, especially in high-speed or high-load situations.

To achieve optimal alignment, ensure the cam track and follower are parallel, and use precision tools for installation.

Adjust the follower for any irregular shapes to fit the track's curve. Check for changes often to keep performance high and extend the system's life.

Proper mounting of cam followers ensures even load distribution and minimizes stress on both the follower and machinery components. This reduces friction, heat build-up, and wear, leading to longer service life and more reliable operation.

Accurate alignment and secure fastening are key to optimal performance and reduced maintenance needs.

In special areas like making airplanes, weaving fabric, and creating clean energy, cam followers solve unique automation problems.

In wind turbines, cam followers in the pitch control system help the blades tilt correctly. This allows the blades to catch the wind better and produce more energy.

In textile manufacturing, cam followers maintain the right tension on the looms. This helps improve fabric quality and lowers production errors. This shows how important they are for handling tricky movement jobs in industrial automation.

Understanding how cam followers work is extremely important. It helps you achieve precision, manage loads effectively, and keeps your machines lasting longer. With such knowledge, you can select the right followers for specific tasks, optimizing performance and reliability across various applications.

Remember to use it to make informed decisions for your industrial needs.

In the vast expanse of mechanical engineering, few mechanisms are as indispensable as the cam and its accompanying cam follower. They not only...

In the industrial sector, machines that work well all the time are essential for good performance and safety. McGill cam followers are just a crucial...

Cam followers play a key role in many machines, helping to change spinning motion into straight-line movement. Understanding what makes cam followers...