How Slewing Bearings Are Made

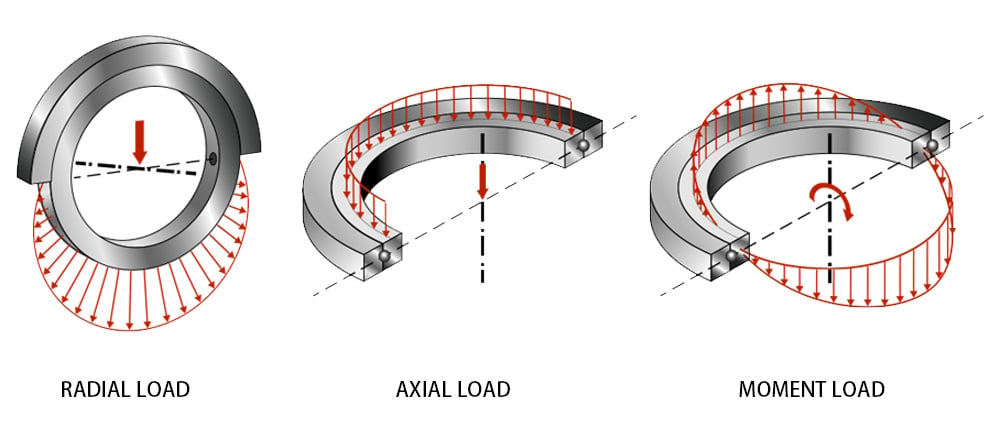

Slewing bearings are essential mechanical components that manage axial, radial, and moment loads. They play a critical role in industries such as...

2 min read

Erik : Aug 27, 2025 2:13:50 AM

Transmission methods for equipment include mechanical, hydraulic, electric, and magnetic. Mechanical transmission is further divided into friction transmission (using belts, chains, etc.), mechanical transmission (couplings, universal joints, etc.) and gear mesh transmission (using gears).

Gear transmission is very common. To determine the bearing's rated service life and select the appropriate size and model of rolling bearings, it is crucial to consider the forces at the gear mesh point and the load transferred to the bearings.

Fig 1 Spur gears, helical gears and herringbone gears

Fig 2 Straight and Spiral Bevel Gears

Fig 3 Hypoid gears and worm gears

Spur gear mesh transmission has no axial force.

Force Analysis and Calculation at Spur Gear Mesh Points:

Radial Force Analysis on Bearings on Both Sides of the Gear Shaft:

The axial forces generated by the gear teeth cancel each other out.

Note: The above bearing force analysis only considers forces from gear meshing. Even in systems without axial force, it is necessary to design locating and floating ends. The use of cylindrical roller bearings at both ends of the gear shaft is shown for ease of understanding the theoretical absence of axial force in gear mesh transmission.

Slewing bearings are essential mechanical components that manage axial, radial, and moment loads. They play a critical role in industries such as...

slewing ring bearings, or slewing bearings, are a fundamental component in numerous industrial machines, particularly in the renewable energy sector....

Ball bearings are unsung heroes of the industrial world, playing an indispensable role in the smooth operation of machinery across a multitude of...