Airframe Control Ball Bearings Vs Radial Ball Bearings in Aerospace

In the intricate realm of aerospace, ball bearings serve a pivotal role, ensuring precision, efficiency, and durability in various mechanical...

3 min read

William

:

Aug 27, 2025 3:52:23 AM

William

:

Aug 27, 2025 3:52:23 AM

Super Precision angular contact ball bearings are at the heart of many high-performance machines and equipment. They are designed to handle high speeds and increased loads with precision. This makes them incredibly versatile and essential for various applications. In this blog, we'll explore the benefits of these precision bearings. We'll also explain why they are essential in industries that need high speed and precise engineering.

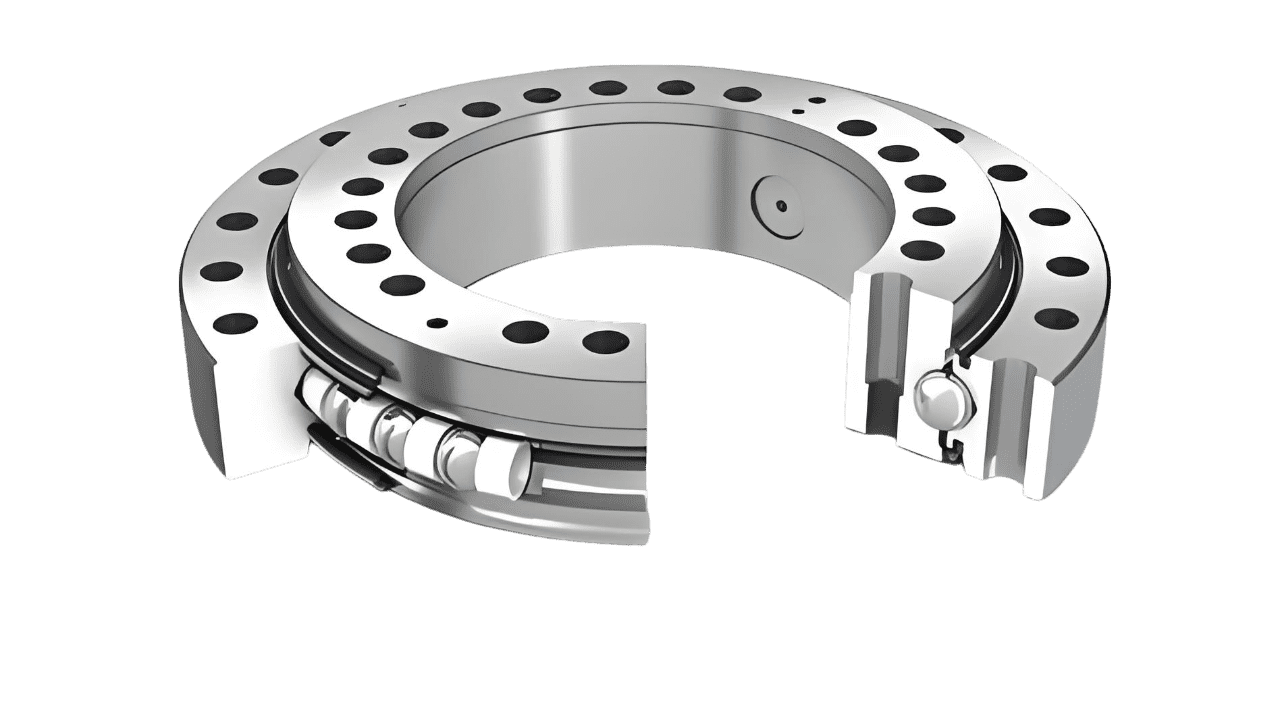

Super Precision angular contact bearings are a type of ball bearing designed to handle both axial and radial loads. They are engineered to operate at ultra-high speeds while maintaining a high accuracy and efficiency. These bearings are commonly used in applications such as machine tools, medical equipment, and aerospace technology.

Super Precision angular contact bearings are made with durable materials like ceramic or steel balls, strong inner and outer rings, and advanced cage designs. These materials are selected for their strength and ability to handle high-stress conditions.

Designs are tailored to specific needs, whether for high speed, heavy loads, or precise tasks. This ensures the right solution is available for various industries, especially when angular contact bearing design must match specific operating conditions.

Here are the benefits of super-precision angular contact bearings. Through them, you'll know why they are essential in high-performance uses.

Super Precision angular contact bearings handle both radial and axial loads. They are key when high load capacity is needed. You’ll find them in high-speed spindles and heavy-duty equipment, where they perform reliably under stress.

These bearings are built for high-speed operation with minimal friction, enhancing efficiency and lowering energy use. This makes them perfect for fast-paced applications like CNC machines and automated assembly lines, where speed capabilities are crucial.

A key feature of Super Precision angular contact bearings is their precise alignment and positioning. This high precision is vital in machine tools and robotics, where any small deviation can affect performance. These bearings offer smooth and accurate operation.

Super Precision angular contact bearings are designed for better rigidity and stability. This is key for high-precision machinery. Industries like manufacturing and automation rely on these bearings for their strong and stable support.

Super Precision angular contact bearings are made with strong materials and advanced design, giving them a long bearing life. They resist wear well, which means fewer replacements and lower costs.

These bearings need less maintenance than standard ones, reducing downtime and costs. Their low upkeep makes them ideal for industries focused on continuous operation and cost efficiency.

Super Precision angular contact bearings are built to reduce noise and vibration. This makes them ideal for quiet operation. They are especially important in medical equipment and consumer electronics, where a quiet environment is crucial.

Super Precision angular contact bearings are known for their strength, speed capabilities, precision, and durability. They are crucial in industries like aerospace, robotics, and medical equipment, where reliable performance is key. Choosing the right bearings can greatly improve efficiency and longevity. For more information and assistance, contact LILY Bearing.

In the intricate realm of aerospace, ball bearings serve a pivotal role, ensuring precision, efficiency, and durability in various mechanical...

Bearings are crucial components in the mechanical world, helping rotating equipment run smoothly and efficiently. Preloading a bearing is an...

Coated bearings are standard bearings. They have a layer of special material on them that makes their surface better. This treatment helps them work...