Ball Bearings vs. Roller Bearings

Bearings are essential parts of machines and equipment. They reduce friction, making it easier for parts to move smoothly. Two main types of bearings...

8 min read

William

:

Aug 27, 2025 4:27:10 AM

William

:

Aug 27, 2025 4:27:10 AM

Choosing reliable bearing suppliers is key to ensuring your machinery works well. It also helps extend the life of your equipment by reducing repairs and failures.

Bearing suppliers and manufacturers provide high-quality bearings. These bearings help machinery run smoothly. They make bearings that fit specific needs. This improves equipment efficiency and reduces downtime.

The blog helps readers find reliable local bearing suppliers and connect with trusted manufacturers. It offers tips on choosing the right ones to meet their needs.

Suppliers act as intermediaries by sourcing bearings from manufacturers and delivering them to end-users. Suppliers manage the delivery of bearings, making sure the right ones reach customers on time. They may also offer services like inventory management, customer support, and advice to help users choose the best bearings.

LILY BEARING is a manufacturer of ball bearings, needle roller bearings, tapered roller bearings, and custom bearings. They also offer associated training and services.

Certifications like ABEC, ISO, ANSI, and ASTM make sure bearings are high-quality. ABEC shows how precise the bearings are, especially for fast or exact uses.

ISO means the manufacturer follows global quality standards. ANSI ensures the product is safe and performs well, while ASTM checks the bearings for strength and reliability. These certifications help you get durable and dependable bearings.

The ABEC rating system measures the precision of ball bearings. The scale ranges from ABEC 1 to ABEC 9, with higher numbers indicating more precision.

Here’s what each class means:

|

ABEC Rating |

Precision Level |

Common Applications |

|

ABEC 1 |

Basic |

General machines, everyday use |

|

ABEC 3 |

Moderate |

Skateboards, small motors |

|

ABEC 5 |

Good balance |

Bicycles, power tools |

|

ABEC 7 |

High |

Robotics, medical devices |

|

ABEC 9 |

Highest |

Aerospace, motorsports |

ANSI and ASTM standards help ensure the quality and consistency of bearings:

Talk to your supplier's technical team to get the best bearings for your needs. They can help you choose the right bearings for your equipment. This ensures better performance and a longer life. Ask questions and share your needs for a customized solution.

Good after-sales support is important for keeping your bearings working well. This includes maintenance, quick replacements, and help with any technical problems. It helps prevent downtime and keeps your equipment running smoothly.

Bearing suppliers can make custom bearings to meet your specific needs. They will work with you to understand things like size, material, and how the bearing will be used. This ensures the bearings fit perfectly and last longer in your machines. Custom bearings are useful when standard ones don’t work for your special requirements.

Traceability means tracking a product from start to finish. It’s important because it helps ensure the bearing is made with good quality. If there’s a problem, traceability helps find and fix it quickly. It also makes sure everyone involved is accountable, keeping the product reliable.

Traceability helps improve quality control by tracking each bearing’s production. It ensures that all parts meet the required standards. If there’s a problem, traceability makes it easy to find and recall faulty bearings quickly.

It also builds customer trust by showing that each bearing is made with care and can be traced back to its source. Customers feel more confident knowing the product is reliable and meets high standards.

|

Criteria |

ABEC 5 |

ABEC 9 |

|

Precision |

Suitable for general use |

High precision for tight tolerances |

|

Applications |

Industrial machinery, conveyors, general equipment |

Aerospace, medical devices, high-performance machinery |

|

Load and Speed |

Medium load and speed |

High load and speed, high performance |

|

Cost |

More affordable |

Higher cost because of precision |

|

Durability |

Good balance for everyday use |

Superior durability in demanding applications |

Reliable bearing suppliers and manufacturers are important for getting high-quality bearings that keep machines working well. Working with trusted suppliers ensures you get the right products. This leads to long-lasting performance.

Following quality standards gives you an edge by making products more reliable and reducing problems. It builds a strong reputation, improves efficiency, and helps your business succeed in the long run.

Find and work with reliable suppliers like LILY Bearing. This will give you high-quality products and help your business succeed.

Bearings are essential parts of machines and equipment. They reduce friction, making it easier for parts to move smoothly. Two main types of bearings...

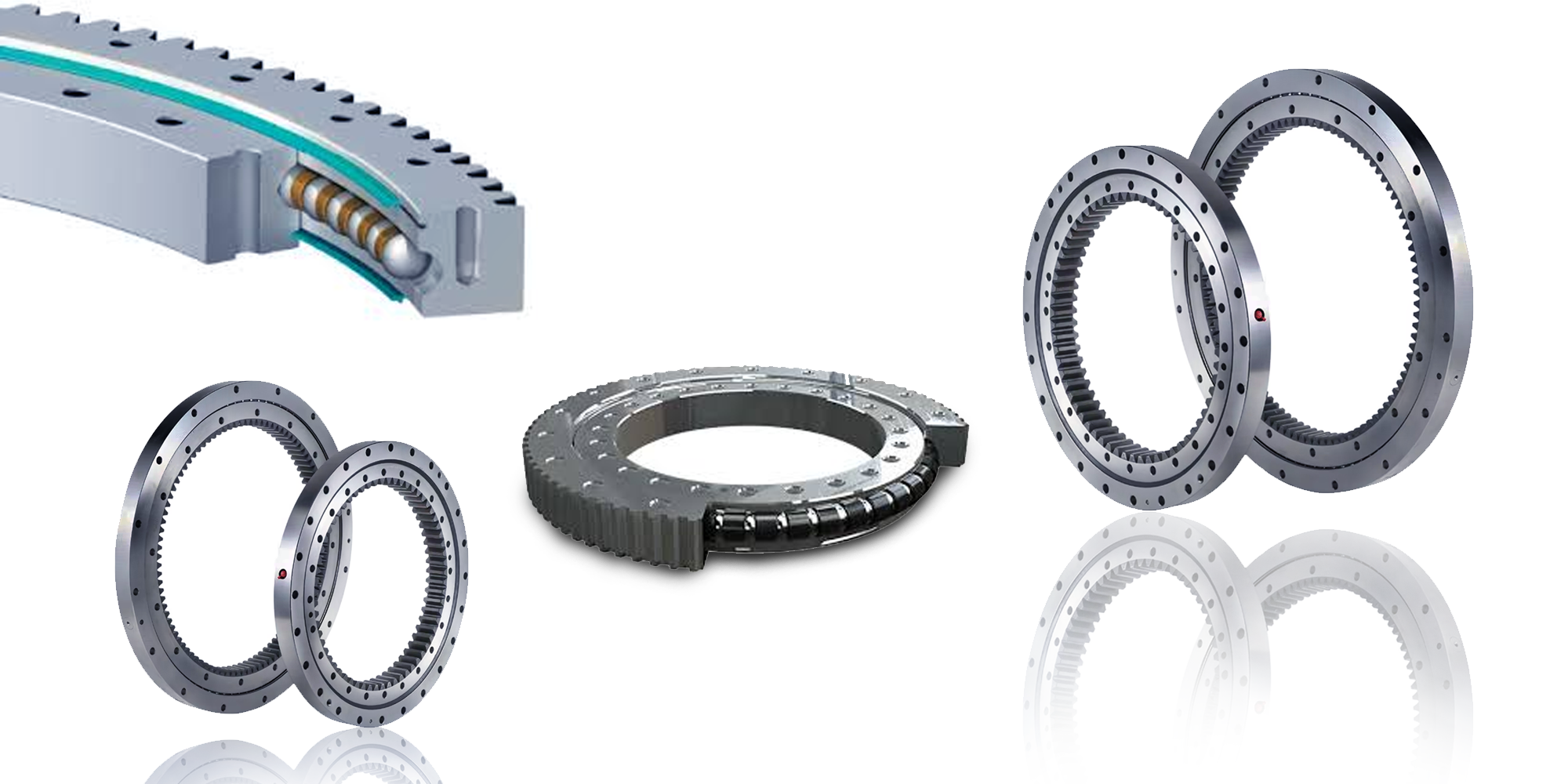

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

Roller bearings are important because they reduce friction and help parts move smoothly. By using rolling instead of sliding, roller bearings help...