Types of Bearings: A Comprehensive Guide

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...

Table of Contents

Bearings are essential parts of machines and equipment. They reduce friction, making it easier for parts to move smoothly.

Two main types of bearings exist: ball bearings and roller bearings.

Ball bearings are great for handling lighter loads and ensuring smooth movement. Roller bearings are designed for heavier loads and tough conditions.

In this blog, we’ll dive into the key differences and similarities between ball and roller bearings.

Ball bearings are a type of rolling-element bearing designed to minimize friction and enable smooth motion. They consist of four main components:

Ball bearings help parts move smoothly by reducing friction.

The balls inside the bearing touch the rings at single points, which lowers friction and makes them great for high-speed use.

This design is perfect for jobs where precision and fast movement are important.

Ball bearings are versatile and can handle different types of loads.

They are commonly used for radial loads, axial loads, and combined loads.

This makes them suitable for a wide range of applications.

Deep Groove Ball Bearings are a type of ball bearing characterized by a simple design. This design enables efficient operation in a wide range of applications.

They have deep grooves on the inner and outer rings that allow them to handle both radial and axial loads.

These bearings are durable, versatile, and commonly used in many machines and devices.

Angular Contact Ball Bearings are designed to handle both radial and axial loads.

They are especially effective at handling axial loads in one direction. The balls are set at an angle to the rings.

This design allows them to support higher speeds and heavier loads compared to regular ball bearings.

These bearings are commonly used in applications like motors, pumps, and high-precision equipment.

Self-Aligning Ball Bearings can adjust to small misalignments between the shaft and housing.

With two rows of balls, they help reduce wear and keep equipment running smoothly.

These bearings are great for machines where keeping parts perfectly aligned is challenging.

Thrust Ball Bearings are designed to handle axial loads, or forces along the shaft.

They have two rings and balls positioned between them to support the load in one direction.

These bearings are commonly used in applications like automotive clutches and gear shafts.

They are also used in other machinery where axial forces need to be managed.

Miniature Ball Bearings are small-sized ball bearings designed for use in compact applications. They are ideal for space-constrained environments.

They work just like regular ball bearings but are much smaller. This makes them ideal for devices like electronics, watches, and small motors.

Despite their size, they are efficient and can handle light loads and high speeds.

Flanged Ball Bearings are ball bearings that have a flange on the outer ring.

This flange helps to keep the bearing in place and prevents it from shifting or moving out of position.

These bearings are commonly used in applications like wheels, rollers, and other machinery where precise positioning is important.

Thin Section Bearings are ball bearings designed with a smaller cross-section compared to standard bearings.

They are lightweight, compact, and can handle both radial and axial loads.

These bearings are ideal for applications where space is limited, such as in robotics, aerospace, and high-precision equipment.

Roller Bearings are a type of bearing that use cylindrical rollers instead of balls. This design helps reduce friction between moving parts.

They are designed to carry heavier loads and are more durable in high-load applications.

The main components of roller bearings include:

Roller bearings reduce friction and support higher load carrying capacity.

Unlike ball bearings, they have line contact with the rings, which spreads the load over a larger area.

This helps them handle heavier loads more effectively, making them perfect for tough industrial machines.

Roller bearings are used in heavy-duty machines. They are designed to handle large loads effectively. This makes them perfect for equipment like construction machines and motors.

Cylindrical Roller Bearings use cylindrical rollers to carry heavy loads. They are great for handling radial loads and are used in machines like motors, gearboxes, and heavy equipment.

Tapered Roller Bearings are designed to handle both radial and axial loads.

They have tapered rollers that make contact with the inner and outer rings at an angle. This design allows them to support heavy loads in one direction while maintaining stability.

These bearings are commonly used in automotive applications, such as wheel hubs, and in heavy machinery.

Spherical Roller Bearings are designed to handle both radial and axial loads.

They have two rows of rollers that can adjust to misalignments between the shaft and housing. This makes them ideal for applications where shaft deflection or alignment issues may occur.

Such applications include mining equipment, motors, and large machinery. Their design allows them to support heavy loads and operate smoothly under tough conditions.

Spherical Roller Thrust Bearings are made to handle heavy axial loads and shaft misalignment.

They have spherical rollers between the rings, allowing them to support heavy loads and adjust to misalignment.

These bearings are used in tough machines like gearboxes and crushers.

Needle Roller Bearings use long, thin rollers to handle heavy loads while saving space. They are lightweight and are often used in cars, transmissions, and small machines.

_compressed.jpg?width=505&height=319&name=Heavy%20Duty%20Needle%20Roller%20Bearings%20(Machined)_compressed.jpg)

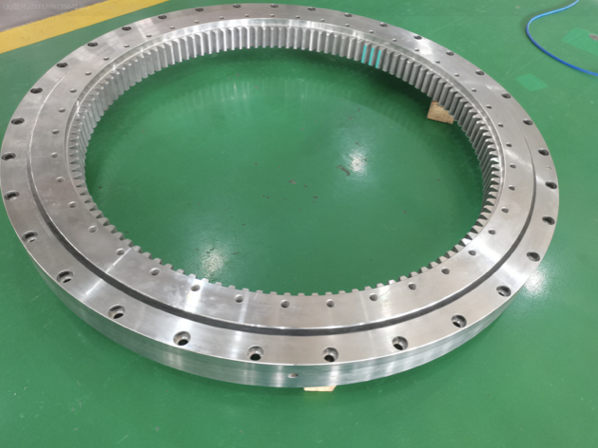

Crossed Roller Bearings have rollers arranged at a 90-degree angle to each other. This creates a crisscross pattern. This design allows them to handle radial, axial, and moment loads all at once.

They are commonly used in applications that require high precision and stability. These include robotic arms, optical equipment, and medical devices.

Ball Bearings use spherical balls to create point contact with the inner and outer race.

This point contact design results in low friction, allowing for smooth movement and high-speed operation.

The reduced friction helps improve efficiency and extend the lifespan of the bearing and the machine it supports.

Roller Bearings use different types of rollers—cylindrical, tapered, needle, or spherical—that make line contact with the raceways.

This design allows them to carry heavier loads than ball bearings by spreading the load over a larger area.

Ball Bearings are best for light to moderate loads. Their design helps reduce friction. This makes them excel in high-speed applications, like motors and electronics.

Roller Bearings can handle heavier radial loads because their rollers spread the load over a larger area.

This makes them perfect for machines that need to carry more weight, like heavy equipment and machinery.

Ball Bearings have low friction, allowing them to rotate smoothly. This helps them perform well in high-speed applications.

They are well-suited for applications in machines such as motors, fans, and electronics.

Roller Bearings experience more friction because of the larger contact area between the rollers and the raceways. This higher friction can limit their performance in high-speed environments.

As a result, they are better suited for applications with heavy loads rather than high-speed operation.

Ball Bearings are more forgiving of misalignment because of their point contact design.

The small contact area between the balls and the raceways provides some flexibility.

This helps the bearing tolerate slight misalignments without causing damage.

This makes them suitable for applications where perfect alignment is difficult to maintain.

Roller Bearings are less tolerant of misalignment because of the line contact between the rollers and the raceways. Even slight misalignment can cause uneven wear or damage.

As a result, they require more precise mounting and alignment to perform effectively and maintain their durability.

|

Feature |

Ball Bearings |

Roller Bearings |

|

Rolling Element |

Balls |

Cylindrical or tapered rollers |

|

Load Distribution |

Point contact, concentrated load |

Line contact, more evenly distributed load |

|

Bearing Type |

Suitable for both radial and axial loads |

Primarily designed for radial loads |

|

Friction |

Higher friction because of point contact |

Lower friction because of line contact |

|

Speed |

Higher speed capabilities |

Lower speed capabilities |

|

Applications |

Smaller, high-speed applications |

Heavy-duty applications |

|

Noise and Vibration |

Can be noisier at high speeds |

Generally quieter and more stable |

|

Cost |

Generally less expensive |

Typically more expensive |

Ball bearings have a low friction coefficient, which allows them to operate smoothly and efficiently.

This design makes them ideal for high-speed applications, as they reduce heat buildup and wear.

It ensures reliable performance in machines like motors, fans, and electronics.

Ball bearings have a compact design, making them ideal for applications with limited space.

They are also versatile, as they can handle both radial loads and axial loads.

This versatility makes them suitable for a wide range of machinery and devices.

Ball bearings have a lower load capacity compared to roller bearings.

The point contact design of ball bearings creates a smaller contact area. This limits their ability to carry heavy loads.

Roller bearings, with their larger contact area, are better suited for handling higher loads.

Ball bearings have a risk of deformation under heavy loads because of their smaller contact area.

When subjected to high pressures, the balls can become flattened, leading to reduced performance and potentially damaging the bearing.

For heavier loads, roller bearings are generally a better choice.

Ball bearings are sensitive to shock and misalignment because of their point contact design. Even minor shocks or misalignments can cause damage or reduce their performance.

This makes them less suitable for applications where misalignment and heavy loads are common.

In contrast, roller bearings handle misalignment better.

|

Advantages |

Disadvantages |

|

High-Speed: Works well at high speeds. |

Lower Load Capacity: Not for heavy loads. |

|

Compact: Takes up less space. |

More Wear: Higher friction than roller bearings. |

|

Low Noise: Quiet at moderate speeds. |

Sensitive to Misalignment: Can wear out faster if misaligned. |

|

Versatile: Handles both radial and axial loads. |

Heat Generation: Can overheat under heavy loads. |

|

Cost-Effective: Generally cheaper. |

Not for Heavy Loads: Not suited for extreme heavy or shock loads. |

Roller bearings have a high load capacity because of their line contact design.

The larger contact area between the rollers and the raceways allows for more effective load distribution.

This makes them ideal for handling heavy radial and axial loads. This makes roller bearings well-suited for heavy-duty applications.

Roller bearings are strong and resistant to deformation under heavy loads.

Their larger contact area helps them handle pressure without losing performance, making them perfect for heavy-duty tasks.

Roller bearings come in different designs like cylindrical, tapered, and spherical to fit various needs.

Cylindrical roller bearings handle radial loads.

Tapered roller bearings handle both radial and axial loads, while spherical roller bearings work well with misalignment. This variety makes them useful in many types of machines.

Roller bearings have higher friction compared to ball bearings. This is because of the larger contact area between the rollers and raceways.

This increased friction can limit their performance in high-speed applications, as it can lead to more heat buildup and wear.

As a result, they are better suited for heavy-duty applications rather than high-speed environments.

Roller bearings have a bulkier design compared to ball bearings, requiring more space for installation.

This makes them less suitable for applications where space is limited, unlike ball bearings, which have a compact design.

Roller bearings are sensitive to misalignment and need careful installation. Even small misalignments can cause damage, so precise mounting is important for proper function.

|

Advantages |

Disadvantages |

|

Higher Load Capacity: Better suited for heavy loads. |

Bulkier Design: Requires more space than ball bearings. |

|

Lower Friction: More efficient at handling heavy loads with less friction. |

Lower Speed: Not suitable for very high-speed applications. |

|

Durable: Lasts longer under heavy loads. |

Noise and Vibration: Can generate more noise and vibration at higher speeds. |

|

Stable: Performs well in high-load or shock-load situations. |

More Expensive: Typically more expensive than ball bearings. |

|

Good for Radial Loads: Ideal for applications with high radial load. |

Sensitive to Misalignment: Can wear out faster if misaligned. |

Ball Bearings are best for lighter loads because they have a small contact area.

Roller Bearings are better for heavier loads because their larger contact area helps them handle more weight.

Ball Bearings are ideal for high-speed applications because they have lower friction.

Their spherical balls create point contact with the raceways, reducing resistance.

This allows for smooth, high speed rotation without generating much heat. This makes them ideal for machines that require high-speed operation, such as motors and fans.

Roller Bearings are better for applications where high load capacity is more important than speed.

Their larger contact area helps them handle heavier loads. This makes them ideal for heavy-duty machinery and equipment.

When selecting the appropriate bearing type, consider these environmental factors:

Ball bearings are great for light loads, fast speeds, and small spaces because they have low friction and are compact.

Roller bearings can handle heavier loads but create more friction, need more space, and must be carefully aligned.

Considering the specific needs of your application is important.

For the best performance, take the time to evaluate these or consult LILY bearing.

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

LILY has supplied assistance in Tesla’s create new products at the Gigafactory, a special custom slewing bearing made by Lily Bearing will soon start...