Ball Bearings vs. Roller Bearings

Bearings are essential parts of machines and equipment. They reduce friction, making it easier for parts to move smoothly. Two main types of bearings...

Industrial bearings play an integral role in the operation of various machinery and vehicles, reducing friction and enhancing performance. This blog aims to dissect the differences between two common types: ball bearings and wheel bearings. By understanding these differences, one can make better decisions for specific applications, ensuring optimal performance and longevity of machinery.

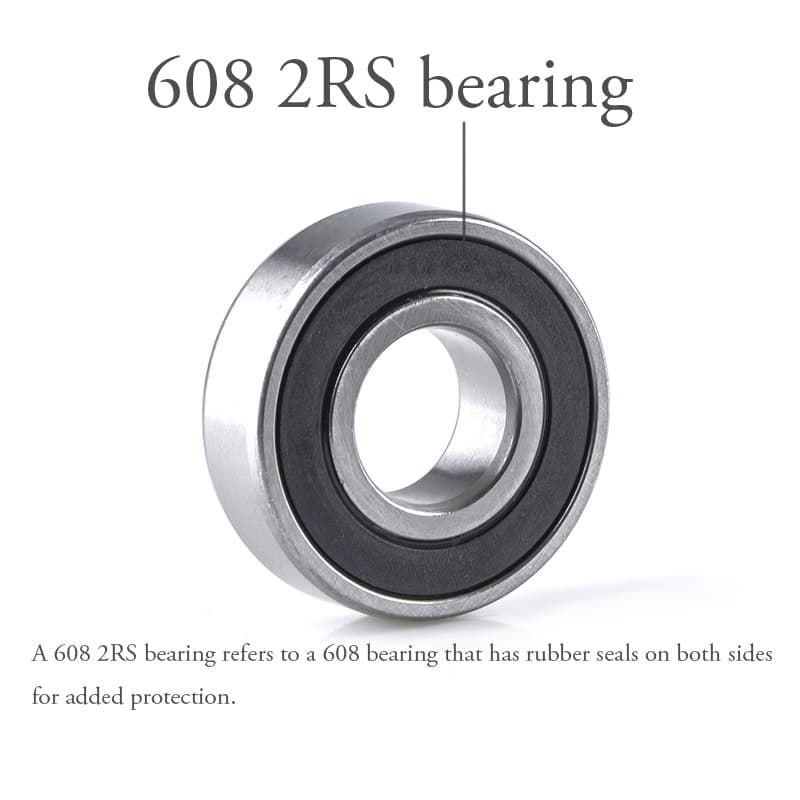

Ball bearings are a type of rolling-element bearing that utilizes balls to maintain the separation between the bearing races. Essentially, they consist of a series of hard steel balls that roll between two rings, known as the inner and outer races. This design minimizes friction and allows for smooth rotation of the assembly.

Ball bearings are widely used in a variety of settings, including:

Despite their advantages, ball bearings have some limitations:

Wheel bearings are a crucial component in vehicle wheel assemblies, connecting the wheel to the axle. Typically comprising an inner and outer ring, with steel balls or rollers in between, they facilitate the wheel's rotation on the axle with minimal friction. These bearings are engineered to support the vehicle's weight while absorbing radial and axial loads from various driving forces, including acceleration, braking, and cornering.

Despite their advantages, wheel bearings can face several challenges:

|

Aspect |

Ball Bearings |

Wheel Bearings |

|

Structure |

Inner and outer rings with steel balls in between. |

Inner and outer rings with steel balls or rollers. |

|

Design Purpose |

Minimize rotational friction; suitable for high-speed, precision applications. |

Support vehicle weight; enable smooth wheel rotation under load. |

|

Applications |

Used in machinery, electronics, and automotive components for high-speed operations. |

Primarily found in automotive wheel systems for vehicle stability and movement. |

|

Performance |

Efficient with reduced friction; ideal for high-speed applications. |

Robust, handling constant vehicle load and varying driving conditions. |

|

Maintenance |

Require precise alignment and lubrication. |

Generally lower maintenance but require regular checks. |

When deciding between ball and wheel bearings, consider:

In essence, ball bearings are optimal for high-speed, precision tasks, whereas wheel bearings are designed for durability under heavy loads in vehicles. Selecting the right bearing is crucial for ensuring optimal performance and safety. At Lily-Bearing, we provide a variety of bearings to meet your specific needs, helping you make well-informed choices for your projects or vehicles.

Bearings are essential parts of machines and equipment. They reduce friction, making it easier for parts to move smoothly. Two main types of bearings...

NBK Bearing Supplies provides distribution services for a wide range of ball bearings and rolling bearings suitable for automotive, aerospace,...

Choosing reliable bearing suppliers is key to ensuring your machinery works well. It also helps extend the life of your equipment by reducing repairs...