Crane Slewing Bearings: Key Features, Benefits and Uses

Crane slewing bearings are essential parts that let cranes make their full 360-degree turns. This ability is crucial for handling various lifting...

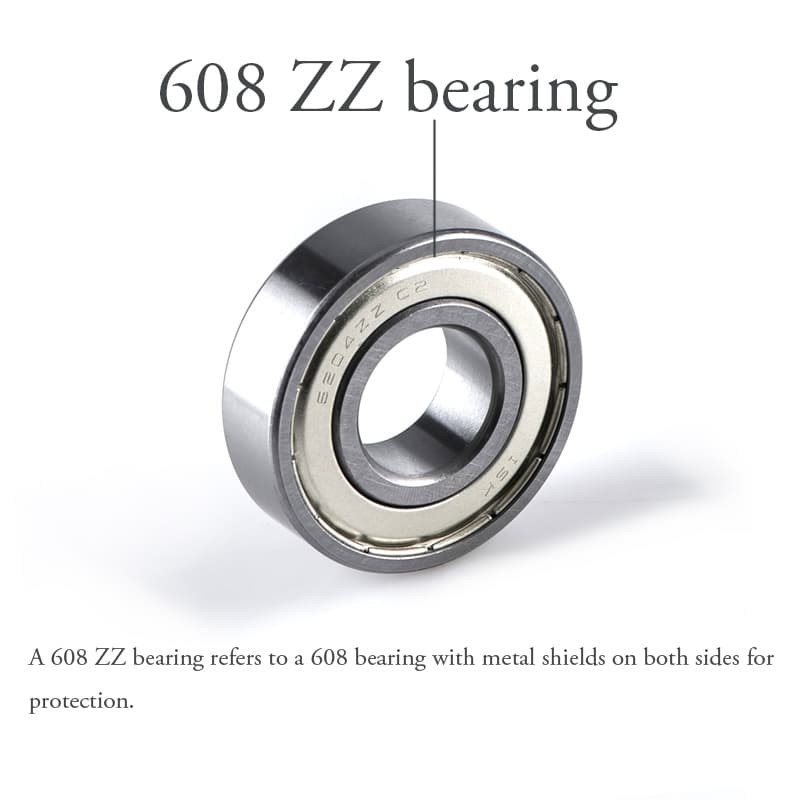

Rolling-element bearings are primarily classified into ball bearings and roller bearings.

The roller bearing category includes cylindrical, tapered, spherical, and needle bearings.

Among these, needle roller bearings are the smallest and lightest, offering distinct advantages for applications where weight and space need to be minimized.

Their long roller length to diameter ratios not only gives them their name but also defines their unique operating properties.

In this blog, we will focus on needle bearings. We’ll cover their advantages, performance, and common uses, as well as any challenges they may have.

Needle bearings are a type of needle roller bearing that use long, thin cylinders to support heavy loads while fitting into small spaces.

Their design helps spread out the weight. This reduces friction and wear, making them great for compact mechanical systems.

Shape and Size: Needle roller bearings use long, thin cylindrical rollers (needles), while other bearings use round or cylindrical rollers. This shape allows needle bearings to fit into tighter spaces while still supporting heavy loads.

Drawn cup needle roller bearings have a thin outer cup filled with needle rollers.

This compact design allows them to handle high loads while taking up less space.

They are often used in car transmissions and industrial machines.

Full-complement needle bearings contain the maximum number of needle rollers without a cage.

This design offers high load capacity but can create more friction since the rollers resembling needles touch each other.

They are useful in tight spaces where extra load support is needed.

Here are the advantages and disadvantages of full complement bearings if you'd like to know.

These have a cage that keeps the needle rollers separated.

This helps them roll smoothly and reduces friction.

Caged needle roller bearings are great for high-speed applications where efficiency matters.

Needle bearings have a compact shape, making them perfect for tight spaces.

Their slim design allows them to fit into small areas without losing strength.

This is why they are often used in automotive transmissions and aerospace components.

These applications require saving space while still handling heavy loads:

The elongated rollers in needle roller bearings create a larger contact area with the raceway. This design allows for better bearing load distribution.

In contrast, ball bearings use smaller spherical balls, and cylindrical roller bearings use standard cylindrical rollers, both of which have less surface contact. This increased surface contact helps distribute the load more effectively.

|

Feature |

Needle Roller Bearings |

Ball Bearings |

|

Rolling Elements |

Needle-shaped rollers |

Spherical balls |

|

Load Capacity |

High load capacity for their size |

Moderate load capacity |

|

Space Efficiency |

Compact design, suitable for tight spaces |

Requires more space because of ball size |

|

Friction |

Generally higher friction due to contact area |

Lower friction because of smaller contact area |

|

Speed Capability |

Lower speed capability compared to ball bearings |

Higher speed capability |

|

Applications |

Automotive, industrial machinery, and compact designs |

High-speed equipment, electric motors, and consumer electronics |

|

Durability |

Good for heavy loads but can wear faster at high speeds |

Longer lifespan in lighter loads and high-speed applications |

|

Cost |

Generally lower cost |

Can be more expensive because of complexity |

|

Feature |

Needle Roller Bearings |

Cylindrical Roller Bearings |

|

Rolling Elements |

Needle-shaped rollers |

Cylindrical-shaped rollers |

|

Size |

Smaller in diameter, longer in length |

Larger diameter, shorter in length |

|

Load Capacity |

High load capacity for their size |

Higher load capacity due to larger contact area |

|

Space Efficiency |

Very compact and suitable for tight spaces |

Requires more radial space than needle rollers |

|

Friction |

Generally higher friction due to more contact area |

Lower friction compared to needle bearings |

|

Speed Capability |

Lower speed capability compared to cylindrical bearings |

Suitable for higher speeds than needle bearings |

|

Applications |

Used in applications with limited space, like automotive and industrial equipment |

Often used in heavy machinery, gearboxes, and large equipment |

|

Durability |

Good for high load but can wear faster at high speeds |

Longer lifespan and better suited for heavier loads |

|

Cost |

Generally lower cost due to simpler design |

Can be more expensive due to the larger size and design complexity |

Needle bearings are known for their lightweight design, making them ideal for industries like aerospace and automotive.

This reduced weight is crucial for improving performance and enhancing fuel efficiency.

By minimizing the weight of moving parts, needle bearings help vehicles and aircraft operate more efficiently, ultimately leading to better overall performance.

Their compact size and ability to handle heavy loads without adding much weight make them a preferred choice in these sectors.

Reference real-world applications in industries such as aerospace, where needle bearings contribute to reducing overall system weight.

Needle roller bearings improve efficiency and reduce power use by lowering friction.

Their long, thin shape spreads the load over a larger area, which cuts down on contact points between moving parts. The rollers roll instead of slide, which helps minimize resistance.

They are also made from materials that reduce friction and can handle misalignment, preventing extra friction. This all leads to smoother operation and less energy wasted, making mechanical systems work better.

A low coefficient of friction means that less force is needed to move parts against each other.

This is a big advantage in applications like transmissions and power tools. In these systems, less friction means smoother operation, so they run more quietly and efficiently.

It also saves energy because the motor doesn't have to work as hard, leading to lower power consumption.

Overall, a low coefficient of friction helps machines perform better, last longer, and use less energy.

Needle roller bearings made from hardened materials like steel are known for their enhanced durability, making them ideal for heavy-duty applications.

The hardness of the steel allows these bearings to resist wear and tear better than those made from softer materials. This means they can handle high loads and harsh operating conditions without degrading quickly.

Full-complement needle roller bearings are designed with all available space filled with rollers, instead of having a cage that separates them.

This means more rollers are in contact with the surfaces, which helps spread out the load evenly.

By sharing the load among more rollers, each roller experiences less stress, reducing wear and tear. This makes the bearings last longer and work better under heavy loads.

They are especially useful in tough applications where reliability and durability are important.

Overall, full-complement designs help extend the life of bearings and improve their performance.

Caged needle roller bearings are specifically designed for high-speed applications because they offer better stability and reduced friction.

In these bearings, a cage holds the rollers in place, keeping them evenly spaced. This prevents the rollers from coming into contact with each other, which reduces friction and helps them roll smoothly.

In Formula 1, needle roller bearings are used in gearboxes and engines. They help reduce friction and allow for faster gear changes.

With the extreme speeds in racing, these bearings provide the durability needed to perform reliably during intense races.

In manufacturing, needle roller bearings are used in high-speed spindles of CNC machines that can reach speeds over 30,000 RPM.

They help the spindles run smoothly with less friction, leading to better-quality parts and longer-lasting tools.

In jet engines and landing gear, needle roller bearings are essential.

They can handle high speeds and temperatures, helping engines run smoothly and safely.

Needle bearings handle oscillating or reciprocating motion more effectively than other bearing types because their design and load distribution.

Their long, slender rollers create a larger contact area with the raceway, allowing them to support heavy loads while minimizing pressure on individual rollers. This helps reduce wear during back-and-forth movements.

Needle bearings are effective in applications like U-joints and connecting rods, where oscillating motion is crucial.

In U-joints, they reduce friction and wear, allowing for smoother movement in driveshafts during vehicle operation.

In connecting rods, needle bearings support the pistons' oscillating motion in engines, minimizing friction and enhancing efficiency.

These features contribute to improved performance and durability in both applications.

Needle bearings excel in environments like planetary gears and compressors, where they can withstand high radial loads more effectively than traditional bearings.

In planetary gear systems, where compact designs and high load capacities are essential, needle bearings help distribute loads evenly, reducing the risk of failure.

Similarly, in compressors, these bearings can endure the intense radial loads generated during operation, ensuring smooth performance and longevity.

Needle roller bearings have a limited tolerance for misalignment, meaning they need to be properly aligned to function well.

If the bearing shafts or components they support are not perfectly aligned, it can cause uneven wear and increased friction. This can lead to overheating and, eventually, bearing failure.

In applications like motors and gearboxes, misalignment can be especially risky. It may cause vibrations, reduce efficiency, and shorten the lifespan of the bearings and the machinery.

In severe cases, it can lead to costly breakdowns and repairs. Therefore, ensuring proper alignment is crucial when using needle roller bearings to maintain performance and reliability.

Needle bearings are primarily designed to handle radial loads, which are forces that push straight down on them from the side.

They work best in applications where these types of loads are common. However, they are not suitable for high axial loads, which are forces that push along the axis of the bearing.

Using needle bearings in situations with high axial loads can lead to failure or damage.

Thrust needle roller bearings are designed to handle axial loads in high-load situations.

They use long, thin rollers (needles) arranged in a cage, allowing them to support heavy loads while saving space.

These bearings have low friction, which improves efficiency, especially at high speeds. Their compact design makes installation easy and often requires less machining than other types of bearings.

Made from durable materials, they provide a long service life.

Needle roller bearings are strong, space-saving, and lightweight, making them a popular choice over ball bearings in confined spaces.

They feature needle-like rollers, typically four times longer than their diameter.

Like all bearings, their main purpose is to minimize friction between moving parts.

Please contact us today to learn more about needle roller bearings or to request a quote.

Crane slewing bearings are essential parts that let cranes make their full 360-degree turns. This ability is crucial for handling various lifting...

In the world of machinery, ball bearings play a pivotal role. They reduce friction and ensure smooth operation of various mechanical systems. But did...

In the world of machinery, the choice of bearings can greatly impact performance. Cross roller bearings, a specific type of roller bearings, offer...