Guilty Pleas In New York Mta Counterfeit Bearing Fraud

The owner of a New York area bearing distributor and the company itself have pled guilty to an array of felony crimes, including fraud, grand...

Needle bearing grease reduces friction and prevents wear, helping machines run smoothly. It also helps machinery last longer by protecting the parts.

Needle bearing grease helps prevent contamination and corrosion in needle bearings by forming a protective barrier around the bearing components. This barrier keeps out dirt, dust, and moisture, protecting the bearings from rust and damage.

Frequent re-greasing or choosing the right needle bearing grease keeps parts lubricated, reducing friction and wear. This helps prevent overheating, rust, and damage, allowing equipment to run smoothly and last longer.

Lubrication keeps parts running smoothly, while needle bearing grease seals out moisture, preventing rust and corrosion. It also cushions parts under high loads, reducing wear and protecting the equipment from damage in tough conditions.

When bearings are under-lubricated, common issues like rust, galling, and contamination can arise:

Here’s a simple table comparing different needle bearing grease types:

|

Grease Type |

Key Features |

Best For |

Load Performance |

Speed Performance |

Environmental Performance |

|

Lithium Complex Grease |

Excellent high-temperature stability, good water resistance, versatile |

Automotive, industrial, and general applications |

Good load-carrying capacity, moderate to high loads |

Performs well at moderate speeds |

Good water resistance, stable in normal environments, but not ideal for extreme conditions |

|

Aluminum Complex Grease |

Better high-temperature and water resistance than lithium complex |

High-speed, high-temperature applications |

Excellent for high loads, especially under extreme conditions |

Performs well at high speeds and extreme temperatures |

Superior water resistance, excellent for harsh, wet environments |

|

Calcium-Based Grease |

Excellent water resistance, limited high-temperature performance |

Marine, agricultural, and moisture-prone environments |

Moderate load-carrying capacity, best for light to moderate loads |

Performs best at low to moderate speeds |

Excellent water resistance, ideal for marine and wet environments but not suited for high temperatures |

|

Synthetic Grease |

Superior high-temperature and heavy-load performance, longer-lasting, expensive |

Extreme conditions, high temperatures, heavy loads |

Exceptional under high loads and extreme pressure |

Performs excellently at high speeds and temperatures |

Best for extreme temperatures, high loads, and challenging environments (e.g., high heat, chemicals) |

Caged bearings often run at higher RPMs. This means they need needle bearing grease that can handle rapid rotation without breaking down. Lighter, tacky greases are ideal for these bearings because they reduce friction at high speeds. They also provide a protective layer that stays in place even under the fast-moving elements.

The tackiness of the needle bearing grease helps it adhere to the bearing surfaces, ensuring continuous lubrication. This also minimizes the risk of contamination or wear. This leads to improved performance and longer bearing life at high rotational speeds.

Full-complement bearings have a larger number of rolling elements. This allows them to carry heavier loads compared to standard bearings. Because these bearings can carry heavier loads, they need stronger needle bearing greases that can handle high pressure. This keeps the bearings lubricated, reduces friction, and prevents wear under heavy use.

Corrosion inhibitors, anti-wear, and extreme pressure additives are important for keeping bearings working well and lasting longer:

In wet or humid operating environments, water-resistant or "marine-grade" grease is essential. It protects bearings from moisture-related damage, ensuring smooth operation. This type of needle bearing grease forms a protective barrier that prevents water from reaching the bearing surfaces. It reduces the risk of rust, corrosion, and wear, ensuring smooth operation and extending the lifespan of the equipment.

When switching needle bearing grease products, it's important to verify compatibility with the existing needle bearing grease to avoid potential issues. Incompatible greases can lead to chemical reactions that affect performance, cause separation, or create sludge. This results in reduced lubrication and possible damage to the bearings.

Always check the product data sheets to understand the characteristics of the new needle bearing grease. Alternatively, consult the manufacturer to ensure the new grease will work well with the current needle bearing grease in the system.

Temperature, speed, and load range all play a crucial role in choosing the right needle bearing grease:

Needle bearing grease viscosity grades indicate the thickness or flow characteristics of the grease. Higher viscosity means thicker grease, which is better for high-load applications. It also provides stronger lubrication and resists breakdown in high-temperature conditions.

Lower viscosity means thinner grease, which flows easily. It is used in low-load or low-temperature situations.

High-speed applications need lower-viscosity needle bearing grease because thicker greases create extra friction and heat. Lower-viscosity greases flow easily, reducing friction and ensuring smooth operation. Specialized needle bearing greases are made for high-speed conditions, providing good lubrication and stability. They protect the bearings from wear and help them last longer.

EP properties are important for handling heavy or shock loads. They help the needle bearing grease maintain its protective layer under intense pressure. Without EP additives, the grease may break down, leading to direct metal-to-metal contact. This can cause wear, damage, and even failure.

EP greases form a strong barrier that can withstand extreme pressure, ensuring the bearings stay lubricated and protected. This helps in high-stress or shock-load conditions, extending the bearings' lifespan.

Friction modifiers, such as molybdenum disulfide (MoS₂), can have both beneficial and detrimental effects depending on the bearing design:

Following the manufacturer’s guidelines for relubrication intervals is important to keep bearings running smoothly. These guidelines help ensure bearings get the right amount of grease at the right time, based on how they are used.

If you don’t follow these intervals, the bearings may not get enough lubrication, causing wear and failure. Regular relubrication helps prevent problems and makes equipment last longer.

Adjust how often you relubricate bearings based on the environment. In wet, dusty, or hot or cold conditions, bearings may need more lubrication to protect them from damage. Needle bearing grease can wear out faster in these environments, so regular relubrication helps keep everything working smoothly.

Check the OEM maintenance manuals for the recommended lubrication schedule. These manuals tell you when to relubricate the bearings. This helps them function properly and extend their lifespan.

If equipment operates in harsh or continuous-duty conditions, adjust the relubrication intervals. In these environments, bearings may need more frequent lubrication. This helps maintain performance and prevent damage.

Look for signs of rust, pitting, or discoloration on the bearings. These can indicate that the needle bearing grease has broken down and is no longer providing proper lubrication.

Note any unusual noises or increased friction, as these could mean the bearings aren't getting enough lubrication. This may signal that maintenance is needed.

Before applying new needle bearing grease, make sure to clean the bearings thoroughly. This step removes old grease, dirt, and any contaminants that could affect performance. Cleaning ensures the new grease can provide proper lubrication, preventing wear and extending the life of the bearings. Always use the right cleaning method to avoid damaging the bearings.

Use the right tools, like a grease gun with needle adapters, to apply grease to bearings in confined spaces. These tools help you reach hard-to-access areas, ensuring that the grease is applied correctly without making a mess. Properly lubricating all areas, even the tight ones, is important for maintaining smooth operation and preventing wear.

Over-greasing can lead to several issues, including grease churn, seal failure, and excess heat:

Using too little needle bearing grease can cause serious issues, such as metal-on-metal contact between the bearing surfaces. This increases friction, leading to premature wear and damage. Over time, this can lead to bearing seizure.

The bearing may stop functioning entirely because of excessive heat and friction. Proper lubrication is essential to prevent these problems and ensure the bearing operates smoothly and lasts longer.

|

Aspect |

Manual Greasing |

Automated Greasing Systems |

|

Process |

Grease is applied manually using grease guns or pumps. |

Grease is delivered automatically, often via drip-feed or force-feed systems. |

|

Pros |

- Cost-effective for small equipment |

- Continuous and consistent lubrication |

|

Cons |

- Requires more labor and time |

- Higher initial setup costs |

|

Best For |

Small operations or equipment with low greasing needs |

Larger systems, high-frequency or high-load applications |

|

System Examples |

Grease guns, manual pumps |

Drip-feed systems, force-feed systems |

To match the greasing method with equipment size, speed, and grease volume:

Pick grease based on temperature, load, speed, and compatibility. Choose the right grease for your equipment's temperature and load.

For needle bearings, you can use Mobil 1 Synthetic Grease for extreme temperatures. Mystik JT-6 is well-suited for high-temperature conditions. Lucas Red & Tacky Grease is ideal for pressure and speed, while Dumonde Tech Premium Grease protects against wear. These greases keep needle bearings safe and running smoothly.

Consulting the OEM guides or trusted bearing manufacturers is always a good idea. For example, LILY Bearing can help confirm the best grease for your specific application. They can provide expert recommendations tailored to your equipment’s needs.

The owner of a New York area bearing distributor and the company itself have pled guilty to an array of felony crimes, including fraud, grand...

Polyurethane rollers play a vital role in the food and beverage industry, providing excellent safety, efficiency , and durability that other...

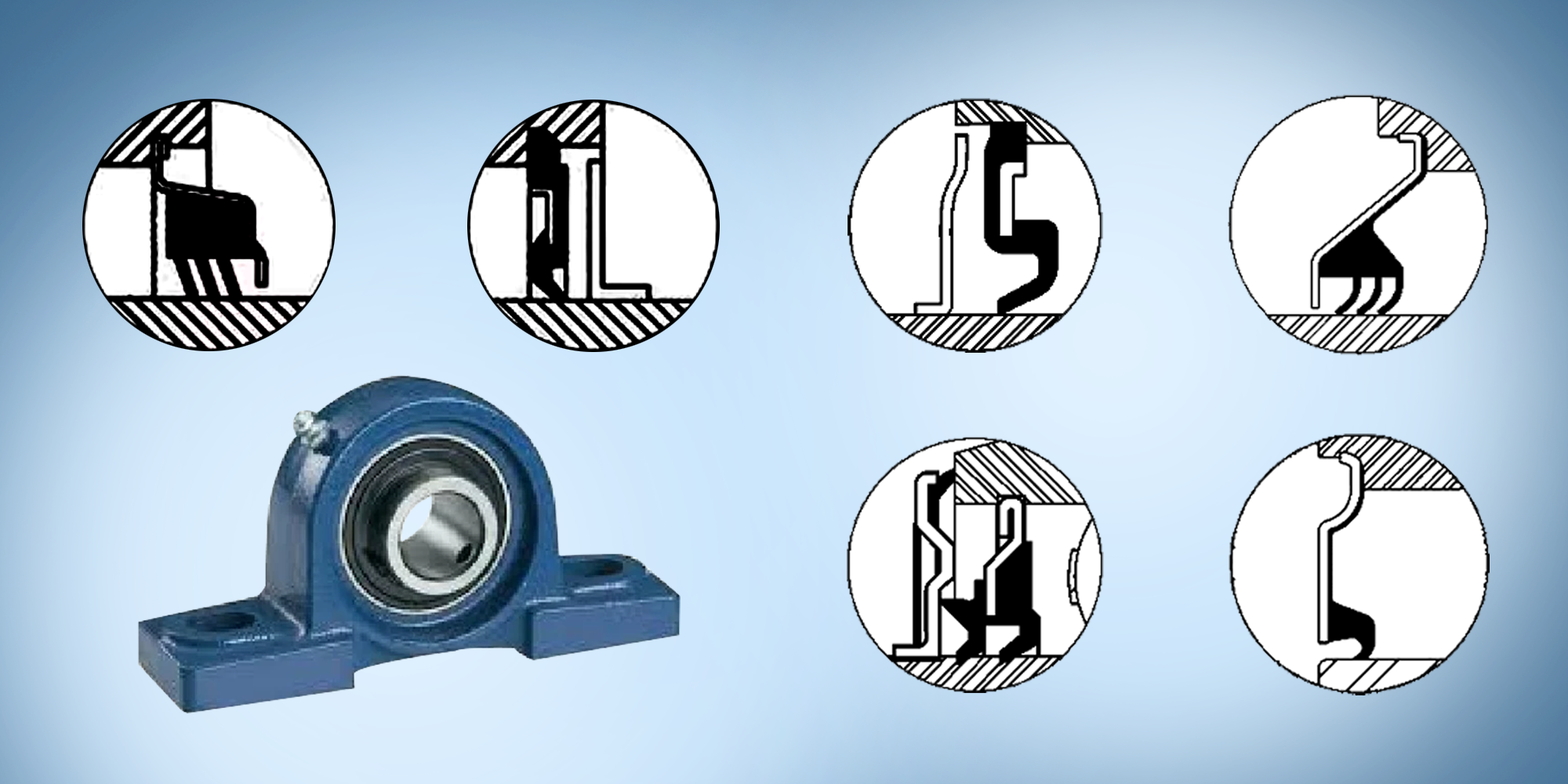

Pillow block bearings are indispensable components in a wide array of industrial equipment, providing robust support for rotating shafts. However,...