608 Bearing: Everything You Need to Know

In the complex and detailed world of mechanical systems, bearings are essential for ensuring smooth rotation and movement of various components. ...

13 min read

Robert

:

Aug 26, 2025 11:39:36 PM

Robert

:

Aug 26, 2025 11:39:36 PM

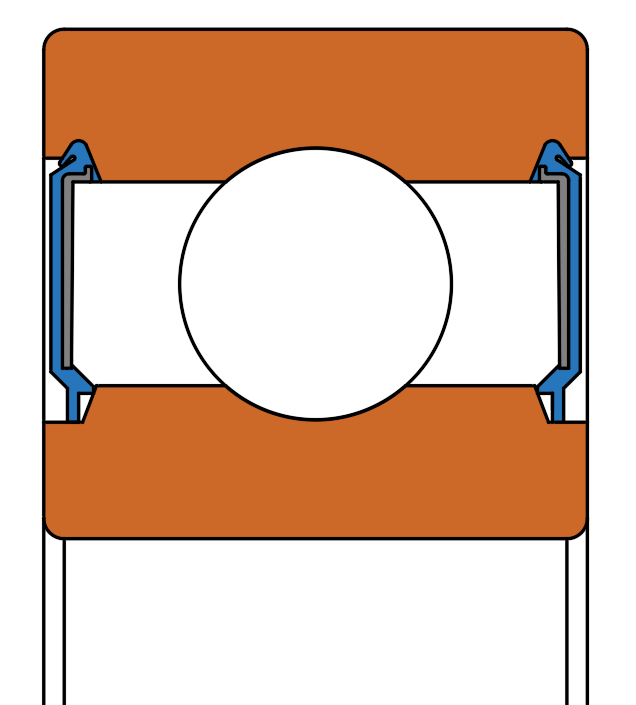

The 6203 bearing is a deep groove ball bearing from the 6000 series. This series is known for its versatility and durability.

6203 single row deep groove ball bearings feature low friction and are designed to minimize noise and vibration. This allows for high-speed operation.

They can support both radial and axial loads in both directions.

They are easy to install and require less maintenance than many other bearing types.

|

Industry |

Application/Equipment |

Description |

|

Home Appliances |

Washing machines, fans, power tools, hair dryers |

Commonly used in motor drives; smooth and quiet |

|

Alternators, power windows, wiper motors, AC motors, idler pulley |

Suitable for high-speed rotation, durable |

|

|

Industrial Machinery |

Motors, pumps, fans, conveyors |

Handles moderate loads with stable performance |

|

Agricultural Equipment |

Lawn mowers, seeders, irrigation systems |

Withstands dust, moisture, and harsh environments |

|

E-bikes/Scooters |

Hub motors, drive systems, control components |

High-speed, long life, and energy-efficient |

|

HVAC Systems |

Fans, electric valves, compressors |

Operates under continuous heat and long runtimes |

|

Fitness Equipment |

Treadmills, exercise bikes |

Smooth rotation with low noise and friction |

|

Small centrifuges, walkers, dental tools |

Requires high precision and reliable operation |

|

|

Packaging & Conveyors |

Rollers, conveyor belts, motor drives |

High reliability for continuous operation |

|

6203 bearing specs |

Metric |

Imperial |

|

Bore Diameter |

17 mm |

0.6693 in |

|

Bore Diameter Tolerance |

-0.008 mm to 0 |

-0.0003 in to 0 |

|

Outside Diameter |

40 mm |

1.575 in |

|

Outside Diameter Tolerance |

-0.011 mm to 0 |

-0.0004 in to 0 |

|

Width |

12 mm |

0.472 in |

|

Width Tolerance |

-0.120 mm to 0 |

-0.0047 in to 0 |

|

6203 Bearing Weight |

65 g |

0.143 lbs |

|

Shoulder Diameter |

24.5 mm |

0.9646 in |

|

Recess Diameter |

34.98 mm |

1.3772 in |

|

Chamfer Dimension |

min. 0.6 mm |

min. 0.0236 in |

|

System of Measurement |

Metric |

– |

|

Tolerance Class |

ABEC-1 |

ABEC-1 |

|

6203 Bearing Size for Mounting |

Metric |

Imperial |

|

Minimum diameter shaft shoulder |

21.2 mm |

0.83 in |

|

Maximum diameter of housing shoulder |

35.8 mm |

1.41 in |

|

Maximum fillet radius |

0.6 mm |

0.024 in |

|

Diameter of shaft abutment |

17.1 mm |

0.674 in |

|

Diameter of housing abutment |

40.3 mm |

1.587 in |

|

Radius of shaft or housing fillet |

1 mm |

0.039 in |

|

Minimum chamfer dimension |

0.6 mm |

0.0236 in |

|

Shoulder diameter outer ring |

33.08 mm |

1.3024 in |

|

Caliber diameter outer ring |

34.38 mm |

1.3539 in |

|

Shoulder diameter inner ring |

24 mm |

0.9449 in |

|

Parameter |

Metric |

Imperial |

|

Basic dynamic load rating |

10,100N |

2,270.6 lbf |

|

Basic static load rating |

4,750 N |

1067.8 lbf |

|

Reference speed |

18,100 RPM |

18,100 RPM |

|

Limiting speed |

26,500 RPM |

26,500 RPM |

|

Fatigue load limit |

285N |

64.1 lbf |

|

Minimum load factor |

0.02 |

0.02 |

|

Calculation factor |

13 |

13 |

|

Tolerance class |

Value |

|

Dimensional tolerances |

P6 |

|

Radial run-out |

P5 |

Carbon Chromium Steel (Gcr15): Commonly used for its excellent hardness, wear resistance, and durability.

Stainless Steel (SGS-tested): Known for its corrosion resistance and ability to withstand harsh environments.

Ceramic: Offers high performance in extreme conditions, such as high temperatures and high-speed applications.

Chromium Steel (52100): Provides high hardness, wear resistance, and is commonly used for high-load and high-speed applications.

Stainless Steel: Offers excellent corrosion resistance and is suitable for high-load applications.

Ceramic: Known for being lightweight, corrosion-resistant, and providing low friction, making it ideal for high-speed applications.

Silicon Nitride: Si₃N₄ Zirconia (Zirconium Dioxide): ZrO₂ Silicon Carbide: SiC

Pressed/Stamped Steel: The steel sheet metal cage are strong and durable, commonly used in standard bearings.

Brass: Provides good durability, often used in high-load bearings.

Nylon: Lightweight and corrosion-resistant, suitable for light-duty applications.

Polymer: Offers low friction and resistance to chemicals and wear.

Nitrile/Buna Synthetic Rubber: It is excellent for sealing and resistant to oils, fuels, and lubricants. This makes it commonly used in general industrial applications.

|

Filling slots |

No filling slots in standard design. |

|

Number of rows |

Single row |

|

Locating feature, bearing outer ring |

No locating feature in the standard design. |

|

Bore type |

Plain bore. |

|

Matched arrangement |

Not typically part of a matched arrangement. |

|

Radial internal clearance |

Standard clearance (C0). |

|

Coating |

Can have coatings like zinc for corrosion resistance or ceramic for high-speed use. |

|

Temperature range |

Metric |

Imperial |

|

Operating temperature min. |

-30 °C |

-22 °F |

|

Operating temperature max. |

120 °C |

248°F |

Note

The 6203RS bearing is a single rubber-sealed deep groove ball bearing. It has a rubber seal on one side to keep out dirt and moisture while keeping the grease inside. It's commonly used in motors, appliances,and machinery for smooth and reliable rotation.

The 6203Z bearing is a single-row deep groove ball bearing featuring a pressed steel cage and a stamped metal cover on one side. This design provides basic protection against contaminants while maintaining simplicity and cost-effectiveness.

A ZZ bearing refers to a bearing with metal shields on both sides to provide dust protection.

These shields are made of stamped metal, preventing dust and debris from entering the bearing. They also maintain relatively low friction compared to full-sealed bearings.

These are often used in general-purpose applications where full sealing isn't necessary, and reduced friction is desired.

|

Aspect |

6203z bearing |

6203zz bearing |

|

Shield Type |

Single metal shield on one side |

Double metal shields on both sides |

|

Material |

Low carbon stamped steel |

Low carbon stamped steel |

|

Grease Retention |

Good, but only on one side |

Good, with better retention because of shields on both sides |

|

Dust/Contaminant Protection |

Blocks larger particles and dust on one side |

Blocks larger particles and dust on both sides |

|

Speed Capability |

Higher speed capability compared to sealed bearings |

Higher speed capability compared to sealed bearings |

|

Protection Level |

Provides moderate protection, more vulnerable to moisture |

Provides slightly higher protection against dust and debris |

|

Temperature Handling |

Suitable for moderate temperature applications |

Suitable for moderate temperature applications |

|

Maintenance |

Requires periodic lubrication on the unshielded side |

Requires less maintenance, as both sides are shielded |

|

Typical Applications |

Motors, electric appliances, light-duty machinery |

Motors, electric appliances, fans, pumps, light-duty machinery |

|

Advantages |

Lower cost, simple design, suitable for less contaminated environments |

Higher dust and particle protection, more balanced coverage |

|

Limitations |

Less effective against moisture or fine contaminants |

Less effective against moisture, still requires lubrication |

Stainless Steel 6203 Bearing:

Ceramic Hybrid 6203 Bearing:

Medical-Grade Bearings:

Higher Precision Classes (P5, P4):

Special Cages:

With Snap Rings: Bearings with snap rings are designed for easy installation. They provide secure retention in position on the shaft or within a housing.

With Locking Grooves: Bearings with locking grooves allow for secure attachment to shafts or housings. This prevents axial movement and improves stability during operation.

Non-Standard Sizes: 6203 bearings are available in custom sizes to meet specific design requirements. This ensures a perfect fit in non-standard housings or components. LILY Bearing specializes in providing custom bearings tailored to your specific requirements.

"6": This indicates the series of the bearing, which refers to the type of bearing. In this case, "6" represents a deep groove ball bearing.

"2": This number indicates the bearing's size series. The "2" suggests it is a medium-sized bearing.

"03": These two digits represent the internal diameter of the bearing in millimeters. For a 6203 bearing, the internal diameter is 17mm.

To learn more about the meaning of bearing numbers, please click here.

Suffixes in bearing designations play a crucial role in identifying specific bearing configurations or features. These may include structural variations, material types, internal bearing clearances, and sealing methods.

They provide detailed information beyond the basic bearing type. This enables users to select bearings that precisely meet the requirements of their applications.

For example, a suffix might indicate a bearing with rubber seals for enhanced protection against contaminants. It could also denote a specific internal clearance suitable for high-speed operations.

Understanding these suffixes is crucial for ensuring optimal performance and compatibility in various mechanical systems.

RS / RSR / DU: These suffixes denote bearings with a single rubber seal on one side. The 'RS' and 'RSR' typically refer to contact seals, while 'DU' indicates a non-contact rubber seal. e.g. 6203DU bearing

2RS / 2RSH / 2RS1 / 2RSR / DDU / LLU / LLB / EE: These suffixes indicate bearings with rubber seals on both sides. '2RS', '2RSH', '2RS1', '2RSR', 'DDU', 'LLU', and 'LLB' represent different variations of contact rubber seals. They differ in design and sealing effectiveness. 'EE' typically refers to bearings with enhanced sealing features.

C3

Bearings with the C3 suffix have a greater internal clearance compared to standard bearings.

This allows for thermal expansion or axial displacement in applications involving higher speeds or varying temperatures. The increased clearance ensures that the bearing operates smoothly even when subjected to these conditions.

Example:

C4

This indicates that the bearing's internal clearance is greater than that of C3. It is typically used for extreme conditions, such as very high speeds and heavy loads. Also suitable for environments with significant temperature fluctuations.

Ideal for applications that need more flexibility and can tolerate higher radial expansion.

Example:

TN9 / TVH / TVP

These suffixes mean the bearing has a nylon cage. Nylon is a strong plastic with good wear resistance and low friction.

It’ commonly used in high-speed or low-lubrication applications.

G15

Brass Cage

The G15 suffix means the bearing has a brass cage. Brass is strong and handles heat better than plastic.

It's often used in heavy-duty applications where strength and heat resistance are important.

BHT / VT

BHT: The BHT suffix means the bearing is made for high-heat environments.

It works well in hot machinery and industrial applications.

VT: This suffix refers to bearings made for high temperatures and harsh chemicals.

It helps the bearing work reliably in tough conditions.

Other Special Suffixes

HT: Bearings with the HT suffix are made for high temperatures.

They are used in applications where temperatures go beyond the normal range.

These bearings are ideal for environments with high thermal stress.

FG: The FG suffix indicates food-grade bearings.

These bearings are made from hygienic materials for use in food processing or medical industries.

They are designed to work in clean and safe environments.

S / SS indicates that the bearing is made from stainless steel.

Example:

SKF

|

Suffix |

Description |

Example |

|

RSH / RS1 |

Rubber-sealed bearing (one or both sides) for better protection against dirt and moisture. |

SKF 6203 2RSH, 6203 2RS SKF |

|

2RZ / RZ |

2RZ: Two shields (one on each side) for dust protection. RZ: One shield for basic protection against dirt and dust. |

6203 RZ Bearing |

|

Explorer |

High-performance bearings designed for long life and low friction in demanding applications. |

SKF 6203 Explorer series |

|

H |

High-temperature bearing, made with materials that can handle elevated heat. |

SKF 6203 H |

FAG / INA

|

Suffix |

Description |

Example |

|

2RSR |

Rubber seals on both sides for protection against dirt, moisture, and contaminants — helps extend bearing life. |

Commonly found in FAG or INA bearings |

|

2HRS |

Rubber seals on both sides with heavy-duty sealing for tough, demanding applications. |

Suitable for challenging environments |

|

TVH / TVP |

TVH: Polyamide cage with high-temperature resistance. TVP: Polyamide cage for general use. |

TVH for high-temperature applications, TVP for general applications |

NTN

|

Suffix |

Description |

Example |

|

LB / LLB |

NTN bearings with rubber seals on both sides provide protection against dirt, dust, and moisture. This ensures smoother operation and a longer lifespan. |

NTN 6203 LB |

|

LU / LLU |

Bearings with rubber seals on both sides offer excellent protection in tough environments by keeping contaminants out. They also help retain lubrication, ensuring long-lasting performance. |

NTN 6203 LU, 6203 LU NTN bearing |

|

LH / LLH |

Bearings with rubber seals on both sides, offering heavy-duty sealing for high-performance applications that need extra protection. |

NTN 6203 LH, 6203 LH NTN bearing |

|

V |

Bearing with grease lubrication, improving performance and lifespan, ideal for applications with limited lubrication access. |

NTN 6203 V |

NSK

|

Suffix |

Description |

Example |

|

DU / DDU |

DU: Bearing with a rubber seal on one side for protection against contaminants. DDU: Bearing with rubber seals on both sides, offering extra protection in harsh environments. |

NSK 6203 DU, NSK 6203 DDU |

|

V / VV |

Shields that protect against larger contaminants like dust and dirt, while allowing for higher-speed performance than sealed bearings. |

NSK 6203 V, NSK 6203 VV |

Timken / Torrington / Fafnir

|

Suffix |

Description |

Example |

|

EE / KK |

Timken bearings with double seals for extra protection against dirt, dust, and moisture. |

6203 2RS Timken, Timken 6203 2RS C3 |

|

NPP / PP |

Bearings with plastic cages and rubber seals on both sides offer durability and protection. They also provide low friction for smooth operation in tough conditions. |

6203 Timken, Timken 6203 NPP |

Suffixes from others

|

Suffix |

Description |

Example |

|

Rxx |

Bearings with rubber seals on one or both sides, protecting against dust, dirt, and moisture. The "xx" indicates specific seal material and design variants. |

6203 RLD bearing, 6203 2DLRS bearing |

|

RLY |

Bearings with rubber seals and an extended lip provide better sealing. They are designed for demanding environments where protection against contaminants is crucial. |

6203 RLYD bearing |

|

RLS |

Bearings with rubber seals and a shielded design, providing both sealing and protection against larger particles. |

6203 2DLRS bearing |

|

RLF |

Bearings with rubber seals and a flanged design, offering better stability and alignment in rigid applications. |

6203 2DLRS |

|

RLD |

Bearings with rubber seals and dual-seals, providing extra protection against contaminants and preventing lubricant leakage. |

6203 RLD |

|

RLYD |

Bearings with rubber seals and an extended lip, offering better sealing against dirt and moisture. |

6203 RLYD bearing |

OEM Special Parts Suffix

|

Suffix |

Description |

Example |

|

LH |

Bearings designed for OEM needs with tailored lubrication or specific internal configurations for unique applications. |

6203 LH bearing, 6203 LH |

|

LHA |

Bearings with special lubrication for better protection and performance in tough applications. The "A" may indicate additional features like reinforced seals or specific internal clearance. |

6203 LHA |

|

LUA |

Bearings with a tailored lubrication system offer superior protection in high-load or high-speed applications. They often use specialized grease to extend lifespan in tough environments. |

6203 LUA bearing |

The 6203 bearing can be replaced by several alternatives with similar performance characteristics, such as:

|

CG425 |

6203RS |

6203LLU |

6203LLB |

6203DDU |

6203VV |

6203.2RSJ1 |

|

6203EE |

6203.2RU |

6203LHX3 |

203PP |

203KSZZ |

6203-2NSL |

99203 |

|

6L025 |

5972K44 |

6153K77 |

6203-2NSE |

6203.2RSR |

6203-2RS |

62032RS |

LILY Bearing offers equivalent replacement options for the 6203 bearing. These options have lower prices and shorter delivery times. They also provide more flexible customization options. You can also refer to a 6203 Bearing cross reference for further alternatives across different manufacturers.

The service life of a 6203 bearing is calculated using its dynamic load rating and the applied load. The most common method to determine bearing service life is using the L10 life. The L10 life represents the number of hours at which 90% of a group of bearings will still be operational.

L10=( C/P )3 ×( 106/60N)

where:

The 6203 bearing is a durable, low-friction component used in high-speed, moderate load applications.

It comes in different versions like sealed, shielded, or open types for various environments.

Commonly used in motors and machinery, it offers reliable performance with proper lubrication and storage.

Explore our wide range of high-quality 6203 bearings and other solutions at LILY Bearing.

In the complex and detailed world of mechanical systems, bearings are essential for ensuring smooth rotation and movement of various components. ...

The deep groove 6204 bearing is a staple in the machinery world, prized for its versatility and reliability. This blog post delves into the specifics...

Whether you’re working with roller bearings, stainless steel ball bearings, or spherical roller bearings, bearing seals play an essential role in...