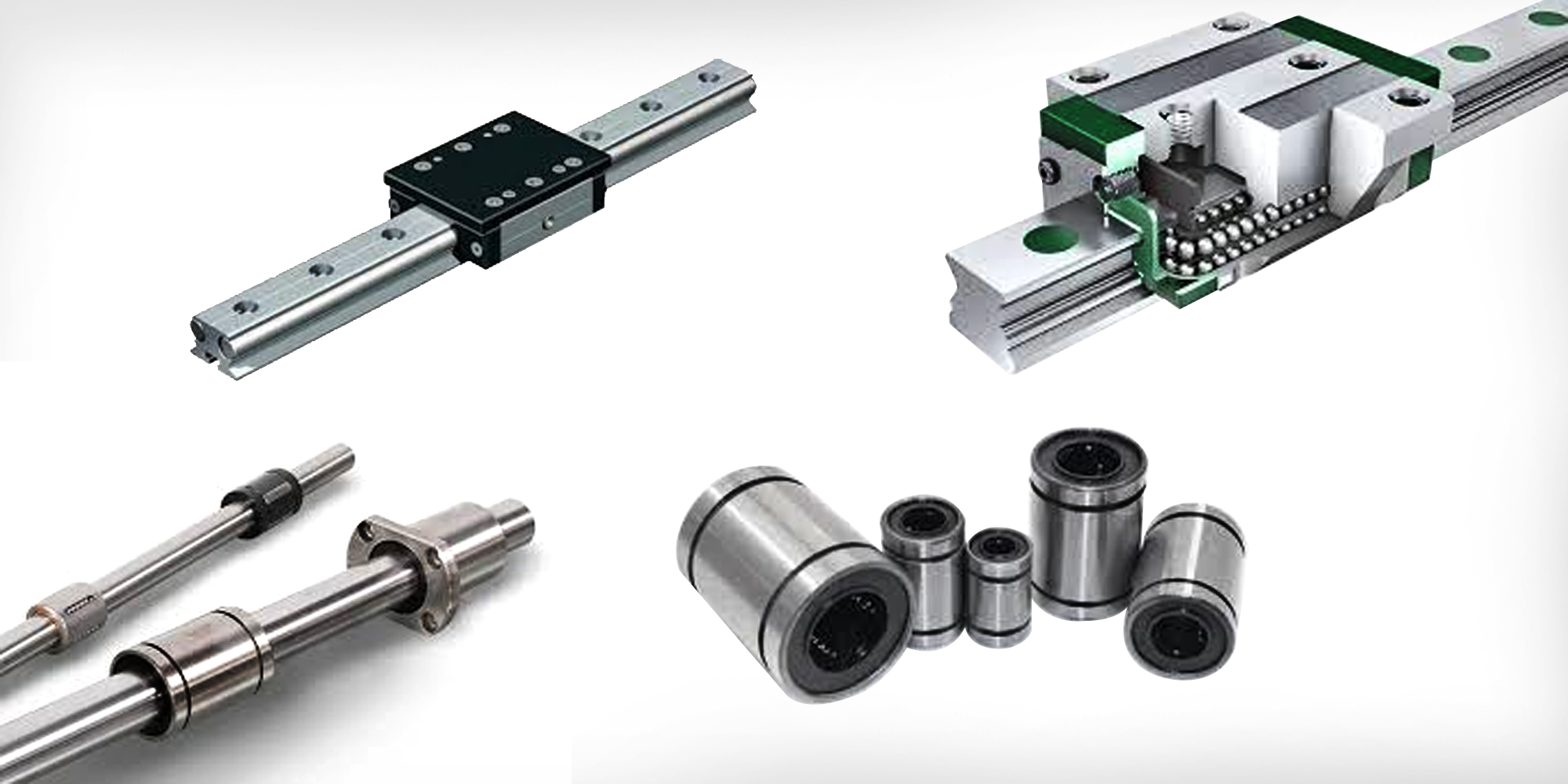

What Is a Linear Bearing?

Linear bearings are essential components in many machines and mechanical systems. They play a critical role in achieving smooth and precise linear...

Table of Contents

In the complex and detailed world of mechanical systems, bearings are essential for ensuring smooth rotation and movement of various components.

Among these engineering innovations, the 608 bearing is recognized for its precision, efficiency, and versatility.

Widely chosen for a range of applications, from skateboards to 3D printers and more, these compact yet powerful bearings have earned their place as a crucial component in numerous industries.

This guide covers the 608 bearing, including its specifications, key benefits and practical applications. It also provides tips on choosing the right bearing for your needs.

A 608 bearing is a type of deep groove ball bearing, typically used in small mechanical systems.

It is characterized by its compact size, making it ideal for applications with limited space.

|

Specification |

Details |

|

Dimensions |

- Bore Diameter: 8mm |

|

Material Options |

- Chrome Steel: Common, durable, and cost-effective for most applications. |

|

608 bearing type

|

- Open: No shields or seals, allowing for easier maintenance but can be exposed to dust or moisture. |

The 608 bearing is designed to handle both radial and axial loads.

It can manage radial loads (side-to-side forces) because of its deep groove structure. This makes it suitable for high-speed applications like skateboards and electric motors.

It also handles axial loads (forces along the bearing's center). This makes it effective in applications such as 3D printers and machinery.

Its bidirectional capability allows it to support these loads in both directions. This offers smooth movement in systems like conveyor belts and small motors.

The 608 bearing is great for both high-speed and low-friction uses.

Its design helps it move smoothly, making it ideal for fast applications like skateboards and electric motors.

It also has low friction, which keeps it running efficiently and reduces wear. This makes it perfect for precise tasks, such as in 3D printers.

Its ability to handle different loads while staying efficient makes it a reliable choice for many machines and devices.

The 608 Open bearing has no seals or shields, which allows it to spin at higher speeds with less friction.

However, this also means it has lower protection against dirt, dust, and moisture, which could cause damage over time.

This type of bearing is best for clean environments where speed is more important than protection.

Ideal for applications like skateboards or similar uses. For environments where debris or harsh conditions are a concern, bearings with shields or seals offer better protection.

The 608 ZZ bearing is equipped with metal shields on both sides, providing protection against dust and dirt. These shields still allow the bearing to spin efficiently.

The metal shields help maintain a balance between speed and protection.

They reduce friction more than rubber seals, allowing the bearing to operate at relatively high speeds.

At the same time, they prevent contaminants from entering and causing damage.

This makes the 608 ZZ ideal for applications that require both protection from debris and smooth operation. Well-suited for uses such as electric motors and power tools.

The 608 2RS bearing has rubber seals on both sides, offering strong protection against dust, dirt, and moisture.

These seals keep the bearing clean, reduce wear, and retain lubrication, ensuring smoother operation.

While this design may add slight friction compared to metal shields, it is ideal for harsh environments.

In these cases, protection from contaminants is more important than speed.

The 608 2RS is commonly used in industrial machinery and other applications that need reliable protection in tough conditions.

The deep groove design of the 608 bearing is key to its high-speed performance.

This design features a smooth, circular raceway that allows the balls to roll efficiently with minimal friction.

The smooth raceway minimizes contact points between the rolling elements and the bearing’s rings.

This reduces friction and enhances the bearing’s performance. This reduction in friction helps the bearing spin more easily, allowing for higher speeds without excessive resistance.

With less friction, there is less energy lost as heat.

This is crucial for maintaining consistent performance at high speeds.

Excess heat can cause the bearing to degrade over time, leading to failure or reduced efficiency.

The deep groove design also helps in evenly distributing loads across the bearing.

This ensures that the bearing can operate at high speeds while maintaining stability and smooth motion.

The 608 bearing is capable of handling high speeds, with typical RPM limits reaching up to 34,000 RPM. This is achievable under ideal conditions.

This high speed is achievable because of the bearing’s design, which minimizes friction and heat buildup.

Additionally, it can handle moderate radial and axial loads effectively.

The inner ring is the component of the bearing that fits around the shaft. It rotates along with the shaft when the bearing is in motion.

Its inner surface is precisely machined to provide a smooth path (raceway) for the rolling elements to travel.

The outer ring is mounted in the housing and stays stationary while the inner ring rotates.

Its outer surface is similarly machined to create a raceway for the rolling elements.

The 608 bearing uses steel or ceramic balls that roll between the inner and outer rings. This design provides smooth movement with minimal friction.

The stainless steel balls are common in regular bearings, offering good durability.

Ceramic balls are used in high-performance bearings for their lower friction and better heat resistance, allowing faster rotation.

This design helps the bearing perform efficiently at high speeds, making it ideal for applications like skateboards and motors.

The cage in a 608 bearing helps separate and align the balls, reducing friction.

By keeping the balls evenly spaced, the bearing cage prevents them from touching each other, which minimizes friction and wear.

This also ensures smoother rotation, especially at high speeds.

The cage plays a key role in maintaining proper ball positioning, helping the bearing run more efficiently.

This also extends the bearing's lifespan, making it ideal for applications like skateboards, motors, and 3D printers.

The 608 bearing is compact, with dimensions of 8mm for the bore diameter, 22mm for the outer diameter, and 7mm for the width.

This small size makes it perfect for devices like skateboards and electric tools where space is limited.

Despite 608 bearing size, it can handle moderate loads and high speeds, providing smooth movement in tight spaces.

This makes it ideal for applications that require both high performance and a small footprint.

Examples include motors, 3D printers, and other small machinery.

The 608 bearing is affordable and easy to find, making it a great choice for many applications.

It offers reliable performance at a low cost, making it an economical choice. This is why it is commonly used in products like skateboards, electric tools, and 3D printers.

With options in steel and ceramic materials, the bearing is available from many manufacturers.

This makes it a convenient and budget-friendly option for both personal and industrial uses.

This combination of low price and wide availability makes the 608 bearing an economical choice for various projects.

Sealed 608 bearings, such as those with rubber seals (2RS) or metal shields (ZZ), require less bearing maintenance.

The seals keep the lubrication inside, reducing friction and wear, which helps the bearing run smoothly for longer.

They also protect the bearing from dirt, dust, and moisture, preventing damage and extending the bearing's life.

| Advantage | Description |

| Small Size | Compact and fits in tight spaces. |

| Smooth Movement | Low friction for fast, efficient rotation. |

| Versatile | Works in many devices like skateboards, 3D printers, and more. |

| Durable | Can handle different types of loads for long-lasting use. |

| Low Maintenance | Seals protect against dirt, reducing the need for frequent upkeep. |

| Easy to Replace | Commonly used, so they’re easy to find and replace. |

| Affordable | Offers good performance at a low cost. |

The 608 bearing is popular in the skating industry because of its durability.

The system also handles both radial and axial loads. Radial loads are forces that push side-to-side, while axial loads are forces that push along the bearing's axis.

This makes the 608 bearing suitable for the movements involved in skateboarding, including quick turns and jumps.

Its durability is key in skateboarding, as the bearing is exposed to dirt, moisture, and constant friction.

Despite this, the 608 bearing maintains smooth rotation and performs well under pressure, even at high speeds.

Its compact size allows for a perfect fit within skateboard wheels, contributing to a fast and smooth ride.

These qualities make the 608 bearing a reliable and affordable choice for both beginner and professional skaters.

In electric motors, 608 bearings are used in components such as the rotor or shaft.

They help prevent heat buildup and wear, ensuring the motor runs smoothly.

This is particularly important for high-speed motors, such as those used in fans or small appliances.

Similarly, in power tools, the bearing ensures smooth rotation of parts like blades or shafts, even under heavy use.

Sealed versions of the 608 bearing protect against dirt and moisture, reducing the need for frequent maintenance.

In 3D printers, 608 bearings help support the movement of the print head and other parts like the belts and axes.

They reduce friction, which helps the printer move smoothly and accurately, leading to higher-quality prints.

The high-speed capability of the bearing is also important for fast movements without compromising precision.

Sealed versions protect the bearing from dust and debris, ensuring longer-lasting performance.

In robotics, 608 bearings are used in moving parts like joints and wheels, allowing for smooth and precise motion.

Their ability to reduce friction is crucial for maintaining the robot’s speed and accuracy. This is especially important in high-speed applications.

The compact size and reliability of the 608 bearing make it ideal for small robots and drones. These applications require both space efficiency and high performance.

|

Material |

Advantages |

Best for |

|

Chrome Steel |

- High strength and durability |

- General-purpose applications |

|

Hybrid Ceramic |

- Lower friction compared to steel |

- High-speed applications |

|

Full Ceramic (e.g., Silicon Nitride) |

- Ultra-low friction |

- Aerospace, medical, and ultra-high-speed machines |

The 608 bearing is typically rated for speeds up to 34,000 RPM. If your application requires higher speeds, consider hybrid ceramic bearings. They can handle more speed because of their lower friction.

Dust can accelerate wear and result in damage to the bearing.

In dusty environments (like outdoors or skateboards), sealed bearings (like 608 2RS or 608 ZZ) are recommended.

These protect the bearing from dust, helping it last longer.

Moisture can cause rust and corrosion, especially in steel bearings.

If your application is exposed to moisture, sealed bearings provide protection against water.

This helps maintain smooth operation of the bearing.

Extreme temperatures can affect the bearing's lubrication and material.

In high-temperature environments, such as in power tools or motors, ceramic or hybrid ceramic bearings are preferable. They can handle heat more effectively than steel bearings.

For cold conditions, special lubricants might be needed to keep steel bearings running smoothly.

Open bearings need to be cleaned regularly to prevent contamination and maintain smooth movement.

Sealed bearings may require re-lubrication over time to keep them running efficiently and extend their lifespan.

By keeping bearings clean and properly lubricated, you ensure optimal performance. This practice also extends the bearing's lifespan, reducing the need for frequent replacements.

To check for wear or damage in a 608 bearing, listen for unusual noises such as grinding or squeaking.

These sounds can indicate internal issues with the bearing.

If the bearing spins more slowly or feels rough, it may have too much friction or need lubrication.

Look for visible signs like rust, cracks, or pitting on the surface.

If any of these issues are present, it may be time to clean, lubricate, or replace the bearing to keep it working properly.

Regular checks help prevent further damage and ensure smooth performance.

The 608 bearing is a versatile and affordable option used in high-speed applications.

Choosing the right 608 bearing for your application is crucial to ensure smooth performance and longevity.

To learn more about bearings Please contact LILY BEARING to discover the ideal bearings for your requirements.

Linear bearings are essential components in many machines and mechanical systems. They play a critical role in achieving smooth and precise linear...

In the demanding realm of food processing and packaging, every component's efficiency and reliability are critical for operational success and health...

In the realm of modern machinery, linear bearings stand out as pivotal elements. Their role is monumental, but it's the meticulous design behind them...