Types of Bearings: A Comprehensive Guide

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...

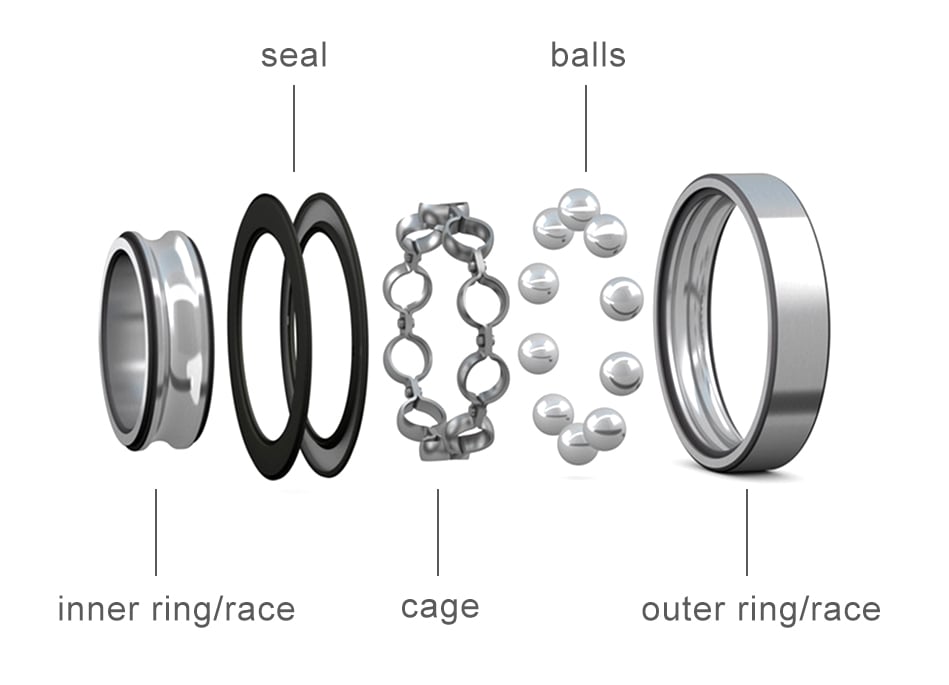

What is a ball bearing? A ball bearing is a type of rolling-element bearing that utilizes balls to maintain separation between the bearing races. The balls roll along the raceway, allowing for smooth rotation of the machinery or equipment.

Ball bearings are used to support rotating, reduce friction and support radial and axial loads in high-load, high-speed applications where reliability and efficiency are critical. Some ball bearing examples include those found in automobile wheels, electric motors, and conveyor systems. Without ball bearings, many machines and equipment would be unable to operate efficiently or safely, making them a vital component in many industries.

the most common type of ball bearing, used in a wide range of applications where high speeds and low friction are required

Angular contact ball bearings:

Angular contact ball bearings:

designed to handle both radial and axial loads simultaneously and ideal for high-speed and precision applications such as machine tools, pumps, and turbines

designed to handle axial loads in one direction and often used in applications that require high axial load capacity, such as automotive transmissions and heavy machinery

designed to compensate for misalignment between the shaft and housing and ideal for applications where there may be shaft deflection, misalignment, or mounting errors

used in smaller applications such as small electric motors and medical equipment

for applications where the bearing needs to be located in a specific position, such as on a shaft that needs to be held in place or on a support structure

Stainless Steel Ball Bearings:

Stainless Steel Ball Bearings:

ideal for use in applications where corrosion resistance is critical, such as in marine environments or where exposure to harsh chemicals is common

offer superior performance and durability, making them an ideal choice for demanding applications where high speed, low friction, and resistance to wear and corrosion are critical

Proper maintenance of ball bearings is essential for ensuring the longevity and efficient operation of machinery and equipment. It can help prevent premature wear and extend the lifespan of the bearing. Maintenance also provides an opportunity to identify potential issues early on, allowing for timely repairs or replacement of the bearing before it fails.

Ball bearings play a crucial role in various industries where smooth and efficient operation is essential. The use of ball bearings reduces friction, improves efficiency, and extends the lifespan of machinery and equipment.

Proper maintenance of ball bearings is crucial for ensuring their longevity and efficient operation, and regular checks and replacement of damaged or worn bearings can prevent machine failure. The importance of ball bearings in different industries cannot be overstated, and their continued development and improvement will undoubtedly lead to even greater efficiency and cost savings in the future.

As a leading supplier of high-quality ball bearings, LILY Bearing offers a wide range of bearings for different applications and industries.

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...

SKF bearings power critical applications from wind turbine gearboxes to EV powertrains, robotics, and medical systems. As a global leader in...

Shielded Vs Sealed Bearings Bearings play a crucial role in numerous applications, reducing friction and enabling smooth, efficient operations....